PN10 DN300 Flat Flange

Product Introduction:

Introducing our revolutionary flange sealing solution, the innovative Waterline Flange with enhanced sealing properties. Designed to optimize contact friction and improve sealing between the convex flange sealing surface and gasket, this product offers unparalleled reliability and efficiency in various industrial applications.

One of the key features of the Waterline Flange is the incorporation of two concentric grooves with a unique triangular interface on the sealing surface. These grooves, aptly named the waterline, are specifically engineered to increase contact friction and sealing capabilities. The initial design included two day waterline grooves, and now we are proud to present the improved version with a dense waterline. This enhanced design ensures a superior sealing property of the surface flange, provided a soft gasket is utilized.

The waterline grooves create a significant difference in the performance of the flange sealing system. By increasing the contact friction and sealing effectiveness, it offers a reliable solution for preventing leakage and minimizing the risk of system malfunction. Additionally, it enhances the durability of the flange, facilitating longer service life and reducing maintenance costs.

One of the remarkable advantages of the Waterline Flange is its versatility. It can be seamlessly integrated into various flange types, such as the commonly used flange flange (also known as K flange). This adaptability makes it suitable for a wide range of industrial sectors, including oil and gas, chemical processing, power generation, and more.

When using the Waterline Flange, the soft gasket acts as a key component in achieving optimal sealing performance. Therefore, it is crucial to select a high-quality, compatible gasket that complements the features of the Waterline Flange, ensuring an airtight seal and excellent overall performance.

Furthermore, our Waterline Flange is meticulously engineered using top-grade materials and cutting-edge manufacturing processes, guaranteeing exceptional quality, reliability, and longevity. Each product undergoes rigorous testing and quality control measures, aligning with industry standards and regulations.

In summary, the Waterline Flange is a game-changer for flange sealing systems. With its innovative design featuring concentric grooves and enhanced sealing properties, this product offers superior reliability, efficiency, and durability. By significantly improving contact friction and sealing capabilities, it prevents leakage, reduces system downtime, and enhances overall performance. Whether it is for industrial, commercial, or residential applications, the Waterline Flange sets the benchmark for high-quality flange sealing solutions. Choose the Waterline Flange for unmatched sealing effectiveness and peace of mind.

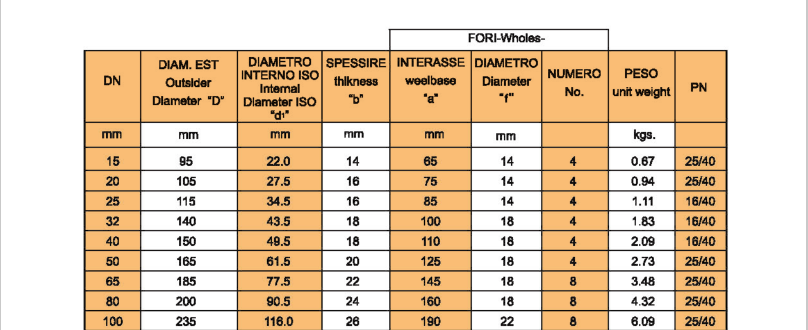

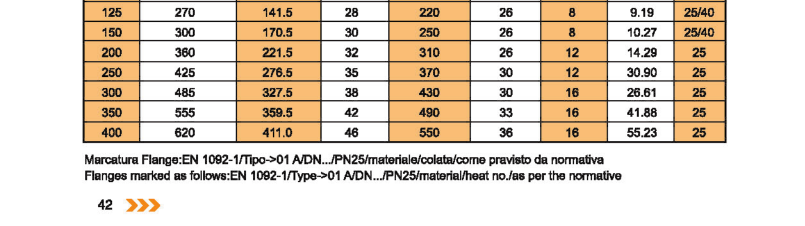

PN10 refers to the pressure rating of a pipe or fitting, indicating that it can withstand a maximum pressure of 10 bar. DN300 refers to the nominal diameter of the pipe or fitting, which is 300 millimeters. Flat Flange refers to the type of flange used in piping systems, which is flat and has no protruding parts.

Advantages of PN10 DN300 Flat flange:

Easy to assemble and dismantle

Suitable for low to medium pressure applications

Good sealing capability due to the flat surface of the flange

Resistant to corrosion and long-lasting.

Applications of PN10 DN300 Flat Flange:

Used in water treatment plants and pipelines for the transport of water and wastewater.

Used in irrigation systems and agricultural pipelines.

Used in chemical and petrochemical industries for the transport of chemicals and petrochemicals.

Used in HVAC systems and building services for the distribution of water and air.

Used in food and beverage industries for the transport of food and drink products.

Used in oil and gas industries for the transport of oil and gas.

Our Company

Jin Runyuan flange of Shandong Machinery CO., LTD is located in the famous "township of the blacksmith"-Shandong Jinan chapter grave area set street agency headquarters, where convenient transportation beautiful environment. Company was founded in 2001, covers an area of 20000 square meters, is a professional manufacturer of forging flange company, main products: Japanese standard, American standard, German standard, the standard also can according to customers drawings or samples processing. Existing fixed assets of 40 million,the annual output 40 million tons.Products are exported to Japan, the United States, Germany, South Korea, Russia, Brazil, South Africa, more than 20 countries and regions, such as product quality deeply the general customers the high praise and trust.

Company strong technical force, professional experience, equiptment, professional production and technical personnel 10 people, the production of 120 front-line workers, management personnel E people, packing, inspection personnel more than 20 people. High quality international most advanced forging machinery processing, assembly, inspection, packaging production lines, product quality meet the national and international standards, and has obtained ISSO9001-2000 quality management system certification, the French classification society certification, China special equipment manufacturing license, pressure vessel manufacturing license.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor