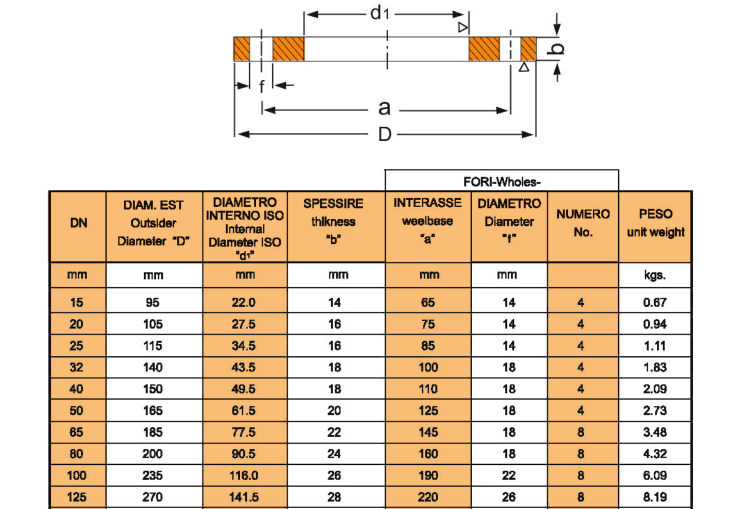

PN16 DN65 Flat Flange

This flange shape is used, normally, in high-pressure and high/low temperatures points that require an unrestricted waft of the fluid conveyed with the aid of way of ability of the piping computing device (the bore of the flange suits with the bore of the pipe.The absence of strain drops prevents poor penalties as turbulence and erosion/corrosion of the metals in the proximity of the flanged joints.The tapered hub lets in a clean distribution of the mechanical stress between the pipe and the weld neck flange and approves the execution of radiographic inspections to discover out practicable leakages and welding defects.The dimension of the flange (NPS and the pipe schedule) shall healthy the dimension of the connecting pipe.

The flat flange design offers several benefits. First and foremost, it provides a flat surface for the pipe or equipment to be connected, ensuring a tight seal. The flat surface allows for easy bolt alignment, simplifying the installation process for plumbers and engineers. Additionally, the flat flange design minimizes turbulence and pressure drop in the system, optimizing the overall flow efficiency.

Jin Runyuan flange of Shandong Machinery CO., LTD is located in the famous "township of the blacksmith"-Shandong Jinan chapter grave area set street agency headquarters, where convenient transportation beautiful environment. Company was founded in 2001, covers an area of 20000 square meters, is a professional manufacturer of forging flange company, main products: Japanese standard, American standard, German standard, the standard also can according to customers drawings or samples processing. Existing fixed assets of 40 million,the annual output 40 million tons.Products are exported to Japan, the United States, Germany, South Korea, Russia, Brazil, South Africa, more than 20 countries and regions, such as product quality deeply the general customers the high praise and trust.

Company strong technical force, professional experience, equiptment, professional production and technical personnel 10 people, the production of 120 front-line workers, management personnel E people, packing, inspection personnel more than 20 people. High quality international most advanced forging machinery processing, assembly, inspection, packaging production lines, product quality meet the national and international standards, and has obtained ISSO9001-2000 quality management system certification, the French classification society certification, China special equipment manufacturing license, pressure vessel manufacturing license.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor