Ansi B16.47 Class 150 Flanges

The ANSI B16.47 Class a hundred and fifty flanges manufacturing manner entails quite a few steps. Here are the most important points and steps concerned in manufacturing ANSI B16.47 Class one hundred fifty flanges:

Material Selection: The first step in the manufacturing technique is choosing the fabulous cloth for the flanges. ANSI B16.47 Class a hundred and fifty flanges are often made from substances like carbon steel, stainless steel, or alloy steel.

c

Cutting: The chosen cloth is then reduce into the preferred form and measurement the use of a reducing computing device or different slicing tools. This step ensures that the flanges are of the right dimensions.

Forming: After cutting, the flange blanks are shaped into the required shape. This can be achieved thru procedures like forging, bending, or rolling. Forming helps to provide the flanges their favored structure and strength.

Machining: The fashioned flanges are then subjected to machining processes. This entails the usage of a number of machines like lathes, milling machines, or drilling machines to take away any extra material, create the preferred floor finish, and add critical threaded holes or bolt patterns.

Heat Treatment: To beautify the cloth residences and enhance the flange's mechanical properties, warmness remedy is frequently carried out. This technique entails heating the flanges to a precise temperature and then cooling them slowly or rapidly, relying on the required properties.

Surface Treatment: Surface remedy strategies like shot blasting or pickling are regularly carried out to cast off scale, rust, or different impurities from the flanges. This helps to enhance the look and corrosion resistance of the flanges.

Quality Control: Throughout the manufacturing process, high-quality manage measures are applied to make certain that the flanges meet the particular standards. This may additionally consist of dimensional checks, hardness tests, visible inspections, or different non-destructive trying out methods.

The facets of ANSI B16.47 Class one hundred fifty flanges include:

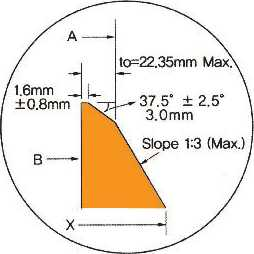

Flange Face: The flange face is flat, with a raised face (RF) or a ring kind joint (RTJ) design, which lets in for perfect sealing when related to matching flanges.

Pressure Rating: ANSI B16.47 Class one hundred fifty flanges are designed to face up to a most strain of a hundred and fifty kilos per rectangular inch (psi).

Bolt Holes: These flanges generally have a precise range and measurement of bolt holes round the circumference to make certain suitable alignment and connection with mating flanges.

Size Range: ANSI B16.47 Class a hundred and fifty flanges are handy in a large vary of sizes, from 26 inches and larger, which permits them to be used in a range of industrial applications.

Compatibility: These flanges typically comply with the dimensions and requirements set by way of the American National Standards Institute (ANSI) and can be used in conjunction with different flanges that meet the identical specifications.

Overall, ANSI B16.47 Class a hundred and fifty flanges are extensively used in industries such as oil and gas, chemical processing, strength generation, and water treatment, the place a dependable and leak-free connection is required.

The American National Standards Institute or the ANSI Class 150 is a device of requirements with regards to the dimensions for 150 lb metal flange dimensions like - threaded, socket weld, slip-on, weld neck, lap joint, and blind flanges. The 150 lb raised face flange dimensions for facing, bolts and studs are additionally blanketed in the ANSI Class.

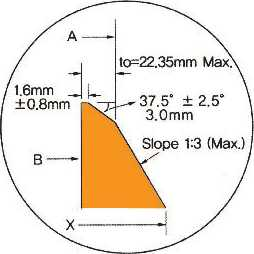

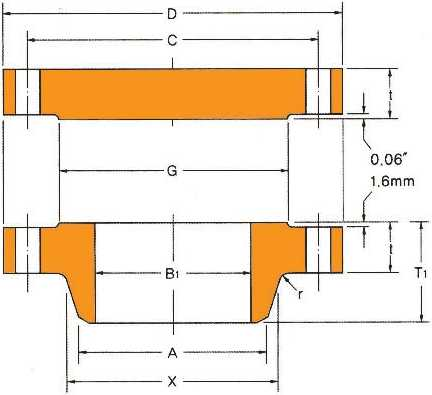

Nominal Pipe Size | Outside Diam | O.D. of Raised Face | Diam. of Hub at Base | Diam. o( Hub at Bevel | BORE | Length Thru Hub | THICKNESS | Radius at Base of Hub | DRILLING | Approximate Weight(kg) | ||||||

Wall Thickness | Blind | Welding | Bolt Circle Diam | Number of Holes | Diam. of Holes | |||||||||||

6.35mm | 9.5mm | 12.7mm | ||||||||||||||

D | G | X | A | B1 | T1 | t | t | r | c | Welding neck | Blind | |||||

26 | 786 | 711.2 | 684.3 | 661.9 | 647.7 | 641.4 | 635.0 | 88.9 | 44.5 | 41.1 | 9.7 | 744.5 | 36 | 22.4 | 54.4 | 169.2 |

28 | 837 | 762.0 | 735.1 | 712.7 | 698.5 | 692.2 | 685.8 | 95.3 | 47.8 | 44,5 | 9.7 | 795.3 | 40 | 22.4 | 63.5 | 205.9 |

30 | 887 | 812.8 | 787.4 | 763.5 | 749.3 | 743.0 | 736.6 | 100.1 | 50.8 | 44.5 | 9.7 | 846.1 | 44 | 22.4 | 68.0 | 246.3 |

32 | 941 | 863.6 | 839.7 | 814.3 | 800.1 | 793.8 | 737.4 | 108.0 | 53.8 | 46.0 | 9.7 | 900.2 | 48 | 22.4 | 77.1 | 293.9 |

34 | 1005 | 920.8 | 892.0 | 865.1 | 850.9 | 844.6 | 838.2 | 110.2 | 57.2 | 49.3 | 9.7 | 957.3 | 40 | 25.4 | 95.3 | 355.2 |

36 | 1057 | 971.6 | 944.6 | 915.9 | 901.7 | 895.4 | 889.0 | 117.3 | 58.7 | 52.3 | 9.7 | 1009.7 | 44 | 25.4 | 108.9 | 403.7 |

38 | 1124 | 1022,4 | 997.0 | 968.2 | 952.5 | 946.2 | 939.8 | 124.0 | 63.5 | 53.8 | 9.7 | 1069.8 | 40 | 28.4 | 131.5 | 494.0 |

40 | 1175 | 1079.5 | 1049.3 | 1019.0 | 1003.3 | 997.0 | 990.6 | 128.5 | 66.5 | 55.6 | 9.7 | 1120.6 | 44 | 28.4 | 140.6 | 565.6 |

42 | 1226 | 1130.3 | 1101.9 | 1069.8 | 1054.1 | 1047.8 | 1041.4 | 133.4 | 68.3 | 58.7 | 11.2 | 1171.4 | 48 | 28.4 | 156.5 | 631.9 |

44 | 1276 | 1181.1 | 1152.7 | 1120.6 | 1104.9 | 1098.6 | 1092.2 | 136.7 | 71.4 | 60.5 | 11.2 | 1222.2 | 52 | 31.8 | 167.8 | 716.2 |

46 | 1341 | 1234.9 | 1205.0 | 1171.4 | 1155.7 | 1149.4 | 1143.0 | 144.5 | 74.7 | 62.0 | 11.2 | 1284.2 | 40 | 31.8 | 197.3 | 827.4 |

48 | 1392 | 1289.1 | 1257.3 | 1222.2 | 1206.5 | 1200.2 | 1193.8 | 149.4 | 77.7 | 65.0 | 11.2 | 1335.0 | 44 | 31.8 | 217.7 | 927.6 |

50 | 1443 | 1339.9 | 1308.1 | 1273.0 | 1257.3 | 1251.0 | 1244.6 | 153.9 | 80.8 | 68.3 | 11.2 | 1385.8 | 48 | 31.8 | 235.9 | 1036.0 |

52 | 1494 | 1390.7 | 1360.4 | 1323.8 | 1308.1 | 1301.8 | 1295.4 | 157.2 | 84.1 | 69.9 | 11.2 | 1436.6 | 52 | 31,8 | 249.5 | 1155.3 |

54 | 1549 | 1441.5 | 1412.7 | 1374.6 | 1358.9 | 1352.6 | 1346.2 | 162.1 | 87.4 | 71.4 | 11.2 | 1492.3 | 56 | 31.8 | 281.2 | 1291.9 |

56 | 1600 | 1492.3 | 1465.3 | 1425.4 | 1409.7 | 1403.4 | 1397.0 | 166.6 | 90.4 | 73.2 | 14.2 | 1543.1 | 60 | 31.8 | 294.8 | 1426.1 |

58 | 1675 | 1543.1 | 1516.1 | 1476.2 | 1460.5 | 1454.2 | 1447.8 | 174.8 | 93.5 | 74.7 | 14.2 | 1611.4 | 48 | 35.1 | 353.8 | 1614.8 |

60 | 1726 | 1600.2 | 1570.0 | 1527.0 | 1511.3 | 1505.0 | 1498.6 | 179.3 | 96.8 | 76.2 | 14.2 | 1662.2 | 52 | 35.1 | 385.6 | 1774.9 |

Our Company

Jin Runyuan flange of Shandong Machinery CO., LTD is placed in the famous "township of the blacksmith"-Shandong Jinan chapter grave area set avenue agency headquarters, where handy transportation beautiful environment. Company was headquartered in 2001, covers an area of 20000 square meters, is a expert manufacturer of forging flange company, main products: Japanese standard, American standard, German standard, the popular also can according to clients drawings or samples processing. Existing fixed assets of forty million,the annual output 40 million tons.Products are exported to Japan, the United States, Germany, South Korea, Russia, Brazil, South Africa, more than 20 nations and regions, such as product quality deeply the general clients the high praise and trust.

Company sturdy technical force, professional experience, equiptment, professional manufacturing and technical personnel 10 people, the production of 120 front-line workers, administration personnel E people, packing, inspection personnel more than 20 people. High quality worldwide most advanced forging machinery processing, assembly, inspection, packaging manufacturing lines, product quality meet the national and worldwide standards, and has obtained ISSO9001-2000 quality administration system certification, the French classification society certification, China special tools manufacturing license, pressure vessel manufacturing license.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor