JPI7S-15-99 Class 150 Flanges

JPI7S-15-99 Class 150 flanges are specifically designed to meet the demanding requirements of industries, including oil and

gas, petrochemical, chemical processing, and power generation. These flanges adhere to the Japanese Performance Institute

(JPI) standards ensuring top-notch performance and compliance with international quality regulations.

One of the primary benefits of JPI7S-15-99 Class 150 flanges is their exceptional strength and durability. Constructed from high-quality materials such as carbon steel, stainless steel, or alloy steel, these flanges exhibit excellent resistance to corrosion, pressure, and temperature fluctuations. Their robust construction enables them to withstand high-stress environments, making them suitable for heavy-duty applications.

Another noteworthy characteristic of JPI7S-15-99 Class 150 flanges is their compatibility with different types of gaskets and seals. These flanges can be easily paired

with various sealing materials such as graphite, PTFE, or spiral wound gaskets, allowing for flexibility and adaptability to different operating conditions. The proper

selection of gaskets ensures a leak-free connection and prolongs the lifespan of the flanges.

Furthermore, JPI7S-15-99 Class 150 flanges are designed to facilitate easy installation and maintenance. Their standardized dimensions and bolt hole patterns allow

for convenient alignment and connection with pipes and equipment. Additionally, these flanges can be easily disassembled without causing damage, enabling

quick repairs or replacements, minimizing downtime, and ensuring uninterrupted operations.

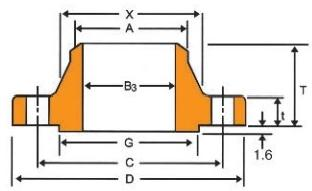

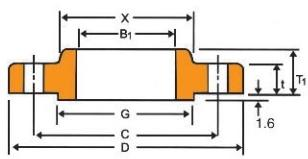

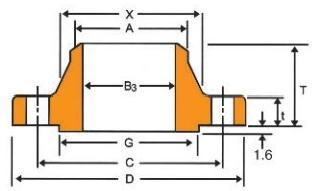

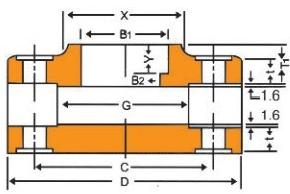

Nominal Pipe Size | Outiside Dia.of Flanges | Dia of Bore | Dia.of Hub at Bevel A | Dia.of Hub at Base | Dia.of Raised Face | Thick of Flanges | Radius of Filet | |||||||||||

Slip-on Socket B1 | Lap-Joint B2 | Welding-Neck,Socket B3 | ||||||||||||||||

JPI | ANSI | |||||||||||||||||

A | B | D | JPI | ANSI | JPI | ANSI | SCH40 | SCH80 | SCH160 | SCH40 | SCH80 | SCH160 | JPI | ANSI | X | G | t | R |

15 20 25 | % % 1 | 89 98 108 | 22.2 27.7 34.5 | 22.4 27.7 34.6 | 23.4 28.9 35.6 | 22.9 28.2 35.1 | 16.1 21.4 27.2 | 14.3 19.4 25.0 | 12.3 16.2 21.2 | 15.8 20.9 26.6 | 13.9 18.8 24.3 | 11.8 15.6 20.7 | 21.7 27.2 34.0 | 21.3 26.7 33.5 | 30.2 38.1 49.3 | 35.1 42.9 50.8 | 11.2 12.7 14.3 | 3 3 3 |

(32) 40 50 | (174) 1% 2 | 117 127 152 | 43.2 49.1 61.1 | 43.2 49.6 62.0 | 44.3 50.4 62.7 | 43.7 50.0 62.5 | 35.5 41.2 52.7 | 32.9 38.4 49.5 | 29.9 34.4 43.1 | 35.1 40.9 52.5 | 32.5 38.1 49.3 | 29.5 34.0 42.9 | 42.7 48.6 60.5 | 42.2 48.3 60.5 | 58.7 65.0 77.6 | 63.5 73.2 91.9 | 15.0 17.5 19.1 | 5 6 8 |

65 80 (90) | 2% 3 3 | 178 190 216 | 71.1 90.0 102.6 | 74.7 90.7 103.4 | 78.7 91.6 104.1 | 75.5 91.4 104.2 | 65.9 78.1 90.2 | 62.3 73.9 85.4 | 57.3 66.9 76.2 | 62.7 77.9 90.1 | 59.0 73.7 85.5 | 54.0 66.7 | 76.3 89.1 101.6 | 73.2 88.9 101.6 | 90.4 108.9 122.2 | 104.6 127.0 139.7 | 22.3 23.9 23.9 | 8 10 10 |

100 (125) 150 | 4 (5) 6 | 229 254 279 | 115.4 141.2 166.6 | 116.1 143.8 170.7 | 116.9 143.0 168.4 | 116.9 144.6 171.5 | 102.3 126.6 151.0 | 97.1 130.8 143.2 | 87.3 108.0 128.8 | 102.3 118.2 154.2 | 97.2 122.3 146.3 | 87.3 109.6 131.8 | 114.3 139.8 165.2 | 114.3 141.2 168.4 | 134.9 163.6 192.0 | 157.2 185.7 215.9 | 23.9 23.9 25.4 | 11 11 13 |

200 250 300 | 8 10 12 | 343 406 483 | 218.0 269.5 321.0 | 221.5 276.4 327.2 | 219.5 271.7 322.8 | 222.3 277.4 328.2 | 199.9 248.8 297.9 | 190.9 237.2 283.7 | 170.3 210.2 251.9 | 202.7 254.5 303.2 | 193.7 242.9 288.9 | 173.1 215.9 257.2 | 216.3 267.4 318.5 | 219.2 273.1 323.9 | 246.1 304.8 365.3 | 269.7 323.9 381.0 | 28.6 30.2 31.8 | 13 13 13 |

350 400 450 | 14 16 18 | 533 597 635 | 358.1 409.0 460.0 | 359.2 410.5 461.8 | 360.2 411.3 462.4 | 333.4 381.0 428.6 | 317.6 363.6 409.6 | 284.2 325.4 366.8 | 333.3 381.0 428.7 | 317.5 363.6 409.6 | 284.2 325.5 366.7 | 355.6 406.4 457.2 | 355.6 406.4 457.2 | 400.1 457.2 505.0 | 412.8 469.9 533.4 | 35.0 36.6 39.7 | 13 13 13 | |

500 600 | 20 24 | 698 813 | 511.0 613.0 | 513.1 616.0 | 514.4 616.0 | 477.8 574.6 | 455.6 547.8 | 408.0 490.6 | 477.8 574.8 | 455.6 547.7 | 408.0 490.6 | 508.0 609.6 | 508.0 609.6 | 558.8 663.4 | 584.2 692.2 | 42.9 47.7 | 13 13 | |

Our Company

Jin Runyuan flange of Shandong Machinery CO., LTD is located in the famous "township of the blacksmith"-Shandong Jinan chapter grave area set street agency headquarters, where convenient transportation beautiful environment. Company was founded in 2001, covers an area of 20000 square meters, is a professional manufacturer of forging flange company, main products: Japanese standard, American standard, German standard, the standard also can according to customers drawings or samples processing. Existing fixed assets of 40 million,the annual output 40 million tons.Products are exported to Japan, the United States, Germany, South Korea, Russia, Brazil, South Africa, more than 20 countries and regions, such as product quality deeply the general customers the high praise and trust.

Company strong technical force, professional experience, equiptment, professional production and technical personnel 10 people, the production of 120 front-line workers, management personnel E people, packing, inspection personnel more than 20 people. High quality international most advanced forging machinery processing, assembly, inspection, packaging production lines, product quality meet the national and international standards, and has obtained ISSO9001-2000 quality management system certification, the French classification society certification, China special equipment manufacturing license, pressure vessel manufacturing license.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor