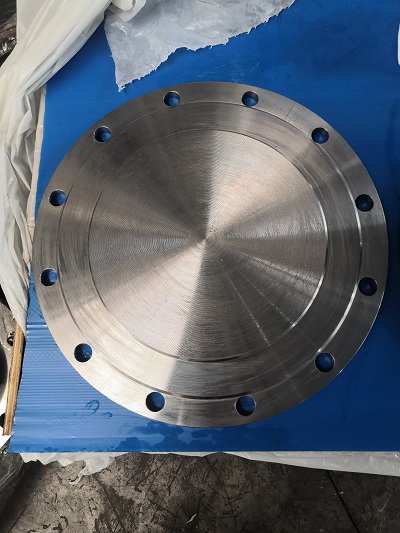

PN10 DN300 Blind flange

To put it simply, the blind plate is a strong flange used to shut the stop of the pipe.

Generally used in the feed water department pipe end. There is a quick part of the pipe area to first stress take a seem to be at used for brief closure.

Flanges are disk-shaped parts, most frequently used in pipeline engineering. Flanges are used in pairs.

In pipeline engineering, flange is basically used for pipeline connection. In the prefer to be part of the pipe, quite a number set up of a flange, low stress pipe can use wire flange, the use of higher than four kg of stress welded flange. Put a seal between the two flanges and fasten them with bolts. Flanges of one of a kind pressures have particular thicknesses and use precise bolts.

Water pumps and valves, when linked with pipes, the local elements of these gear are additionally made into the corresponding flange shape, moreover considered as flange connection.

All in the two planes in the periphery of the use of bolt connection at the equal time closed connection parts, usually regarded as "flange", such as the connection of air drift pipe, this sort of factors can be known as "flange category parts".

But this connection is completely a segment of the equipment, such as the connection of the flange and the water pump, it is now no longer correct to name the water pump "flange parts". Relatively small, such as valves, can be known as "flange parts". Flange connection is an vital connection mode in pipeline construction. Flange connection is the two pipes, pipe fittings or equipment, respectively consistent on a flange plate, between the two flanges, plus flange pad, bolted together to complete the connection. Some pipe fittings and tools have their very very own flange, additionally belong to the flange connection.

The PN10 DN300 Blind flange is a kind of flange that is used to shut off or seal the quit of a pipeline. It is designed to be bolted onto any other flange or pipe end.

The manufacturing procedure for a PN10 DN300 Blind flange normally includes the following steps:

Material selection: The flange is commonly made from a long lasting and corrosion-resistant fabric such as carbon steel, stainless steel, or alloy steel.

Cutting and shaping: The uncooked cloth is reduce into the preferred form the usage of slicing equipment and machinery. The flange is normally a round disc with holes for bolts round its perimeter.

Drilling holes: Holes are drilled into the flange to enable for the attachment of bolts. The dimension and wide variety of holes rely on the particular necessities of the flange.

Machining and finishing: The flange is machined to make sure a easy end and particular dimensions. This can also contain strategies such as turning, milling, or grinding.

Surface treatment: The flange is regularly handled to enhance its resistance to corrosion or to furnish a ornamental finish. Common floor remedies consist of galvanizing, painting, or making use of a protecting coating.

Quality control: The completed flange undergoes rigorous inspection to make certain it meets the required requirements and specifications. This might also contain visible inspection, dimension measurement, and checking out for elements such as electricity and leak resistance.

Now let's talk about some of the key elements of a PN10 DN300 Blind flange:

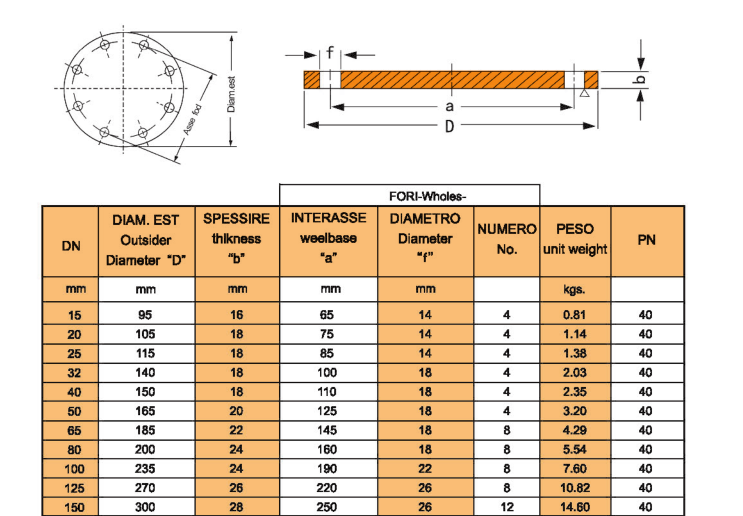

Pressure rating: The PN10 ranking shows that the flange is designed to deal with a most strain of 10 bar. This makes it appropriate for a extensive vary of applications.

Size and dimensions: The DN300 designation refers to the nominal diameter of the flange, which is 300mm. This measurement is generally used in industrial functions such as oil and gasoline pipelines.

Blind design: The blind flange is stable and does no longer have an opening or connection point. It is used to shut off the stop of a pipeline or vessel and offers a leak-proof seal.

Bolt holes: The flange has evenly spaced bolt holes round its circumference, which permit it to be bolted onto every other flange or pipe end. The variety and dimension of bolt holes rely on the precise necessities and standards.

Corrosion resistance: The cloth choice and floor cure of the flange make certain excessive resistance to corrosion, making it appropriate for use in harsh environments.

Versatility: The PN10 DN300 Blind flange can be used in a range of industries and applications, such as oil and gas, chemical processing, water treatment, and more.

Overall, the PN10 DN300 Blind flange presents a dependable and high quality answer for closing off pipelines and making sure a tightly closed and leak-proof seal.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor