PN10 Flanges GOST 12820-80

Flanges play a crucial role in the functioning and reliability of industrial piping systems. They are designed to connect pipes,

valves, pumps, and other equipment, ensuring a secure and leak-proof connection. When it comes to choosing the right

flanges for your piping system, PN10 flanges come highly recommended. Specifically, the GOST 12820-80 standard is widely

recognized and preferred in various industries.

PN10 flanges, in accordance with the GOST 12820-80 standard, are engineered to withstand pressure ratings of up to 10 bar.

This makes them suitable for a range of applications, including water supply networks, gas pipelines, chemical plants, and

industrial infrastructure projects. These flanges provide a strong and durable connection, even under high-pressure

conditions, ensuring the safety and efficiency of the piping system.

The GOST 12820-80 standard is a set of technical requirements and specifications established by the Russian standardization authority. This standard ensures the

compatibility of flanges produced by different manufacturers, allowing for interchangeability and easy installation. GOST 12820-80 flanges are manufactured with

precise dimensions and tolerances, ensuring a perfect fit and eliminating the risk of leaks or failures.

One of the key advantages of PN10 flanges, in accordance with the GOST 12820-80 standard, is their versatility. These flanges are available in a wide range of

materials, including carbon steel, stainless steel, and alloy steel. This allows you to choose the most suitable material based on your specific application requirements

such as compatibility with the transported fluid, temperature, and corrosion resistance.

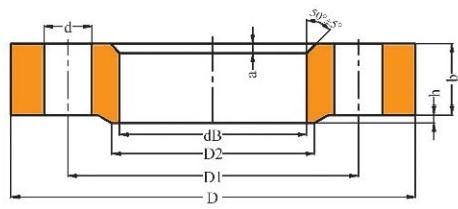

DN | dB | D | D1 | D2 | h | b | d | Number of holes | a | Weight kg |

15 | 19 | 95 | 65 | 47 | 2 | 10 | 14 | 4 | 2 | 0.51 |

20 | 26 | 105 | 75 | 58 | 2 | 12 | 14 | 4 | 2 | 0.74 |

25 | 33 | 115 | 85 | 68 | 2 | 12 | 14 | 4 | 2 | 0.89 |

32 | 39 | 135 | 100 | 78 | 2 | 14 | 18 | 4 | 2 | 1.4 |

40 | 46 | 145 | 110 | 88 | 3 | 15 | 18 | 4 | 3 | 1.71 |

50 | 59 | 160 | 125 | 102 | 3 | 15 | 18 | 4 | 3 | 2.06 |

65 | 78 | 180 | 145 | 122 | 3 | 17 | 18 | 4 | 3 | 2.8 |

80 | 91 | 195 | 160 | 133 | 3 | 17 | 18 | 4 | 3 | 3.19 |

100 | 110 | 215 | 180 | 158 | 3 | 19 | 18 | 8 | 3 | 3.96 |

125 | 135 | 245 | 210 | 184 | 3 | 21 | 18 | 8 | 3 | 5.4 |

150 | 161 | 280 | 240 | 212 | 3 | 21 | 22 | 8 | 3 | 6.62 |

200 | 222 | 335 | 295 | 268 | 3 | 21 | 22 | 8 | 3 | 8.05 |

250 | 273 | 390 | 350 | 320 | 3 | 23 | 22 | 12 | 3 | 10.65 |

300 | 325 | 440 | 400 | 370 | 4 | 24 | 22 | 12 | 4 | 12.9 |

350 | 377 | 500 | 460 | 430 | 4 | 24 | 22 | 16 | 4 | 15.85 |

400 | 426 | 565 | 515 | 482 | 4 | 26 | 26 | 16 | 4 | 21.56 |

500 | 530 | 670 | 620 | 585 | 4 | 28 | 26 | 20 | 4 | 27.7 |

600 | 630 | 780 | 725 | 685 | 5 | 31 | 30 | 24 | 5 | 39.4 |

700 | 720 | 895 | 840 | 800 | 5 | 34 | 30 | 24 | 5 | 59.46 |

800 | 820 | 1010 | 950 | 905 | 5 | 37 | 33 | 24 | 5 | 79.16 |

900 | 920 | 1110 | 1050 | 1005 | 5 | 40 | 33 | 28 | 5 | 94.13 |

1000 | 1020 | 1220 | 1160 | 1110 | 5 | 43 | 33 | 28 | 5 | 118.43 |

1200 | 1222 | 1455 | 1380 | 1330 | 5 | 51 | 39 | 32 | 5 | 197.44 |

1400 | 1420 | 1675 | 1590 | 1530 | 5 | 60 | 45 | 36 | 5 | 278.92 |

1600 | 1620 | 1915 | 1820 | 1750 | 5 | 70 | 52 | 40 | 5 | 422.65 |

Our Company

Jin Runyuan flange of Shandong Machinery CO., LTD is located in the famous "township of the blacksmith"-Shandong Jinan chapter grave area set street agency headquarters, where convenient transportation beautiful environment. Company was founded in 2001, covers an area of 20000 square meters, is a professional manufacturer of forging flange company, main products: Japanese standard, American standard, German standard, the standard also can according to customers drawings or samples processing. Existing fixed assets of 40 million,the annual output 40 million tons.Products are exported to Japan, the United States, Germany, South Korea, Russia, Brazil, South Africa, more than 20 countries and regions, such as product quality deeply the general customers the high praise and trust.

Company strong technical force, professional experience, equiptment, professional production and technical personnel 10 people, the production of 120 front-line workers, management personnel E people, packing, inspection personnel more than 20 people. High quality international most advanced forging machinery processing, assembly, inspection, packaging production lines, product quality meet the national and international standards, and has obtained ISSO9001-2000 quality management system certification, the French classification society certification, China special equipment manufacturing license, pressure vessel manufacturing license.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor