PN10 DN1400 Flat Flange

Flange is a kind of connecting piece that can connect pipes, valves, and equipment. It is an essential part of any piping system as it allows for easy disassembly and adjustment. Flanges offer many advantages, such as flexibility, reliability, and safety, making them a popular choice in the pipeline industry.

One of the main advantages of flanges is their flexibility. They are easy to disassemble and adjust, which means they are perfect for use in systems that require frequent changes. It allows for easy maintenance, inspection, and repair of the piping system. Flange connections make it easier to replace or upgrade equipment without disturbing the rest of the system. This flexibility saves time and money and ensures that the piping system is always up to date.

Another advantage of flanges is that they are reliable. Flange connections are strong and durable, meaning that they can withstand high temperatures and pressures. The flange is designed to distribute the load equally across the bolts, preventing any localized stress on the pipe walls. This even distribution of pressure reduces the risk of leaks, making flanges a reliable choice for critical applications.

Safety is also an important advantage of flanges. They are designed to securely connect pipes, valves, and equipment, ensuring that the system can withstand the pressures and temperatures it is subjected to. Flange connections can be bolted together tightly, which prevents any movement, reducing the risk of leaks or accidents. The use of flanges also makes it easier to shut down the system in case of an emergency, preventing any further damage or accidents.

In addition to these advantages, flanges also offer many other benefits. They are easy to install, saving time and resources. They are also available in a wide range of materials, including stainless steel, carbon steel, and aluminum, allowing for customization based on the requirements of the system.

However, it is essential to ensure that flanges are installed correctly to prevent accidents. Any misalignment or over-tightening of the bolts can cause the flange to break, resulting in leaks or even explosions. Therefore, it is crucial to follow the manufacturer's instructions and industry best practices when installing flanges. Regular maintenance and inspection of the system can also help detect any potential issues and prevent any accidents.

In conclusion, flanges are a versatile and reliable connecting piece that offer numerous advantages in the pipeline industry. Their flexibility, reliability, and safety make them a popular choice for many applications. However, it is essential to install and maintain flanges correctly to ensure their safety and effectiveness. By following best practices and manufacturer's instructions, flanges can provide a secure and efficient solution for connecting pipes, valves, and equipment.

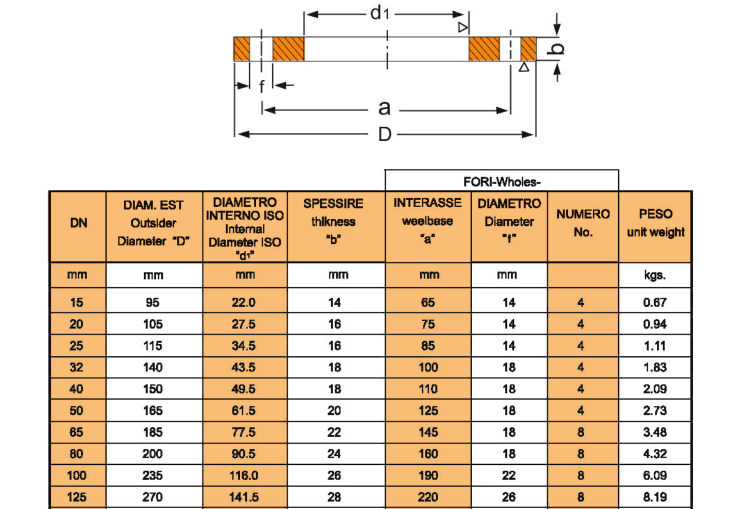

PN10 refers to the pressure rating of the flange, which means it can withstand up to 10 bar of pressure. DN1400 refers to the size of the flange, which has a nominal diameter of 1400 mm (or approximately 55 inches). A flat flange means that the sealing surface of the flange is flat and not raised or recessed like in other types of flanges.

Advantages:

High pressure rating: PN10 rating implies that it can withstand high pressure up to 10 bar.

Cost-effective: Compared to other types of flanges, flat flanges are generally less expensive.

Easy to install: Flat flanges are relatively easy to install and do not require specialized tools or equipment.

Applications:

Water distribution networks: The PN10 DN1400 flat flange is commonly used in water distribution networks for pipelines that carry large volumes of water.

Oil and gas industry: The high pressure rating and large size make it ideal for oil and gas pipelines.

Chemical industry: The flat flange is also used in the chemical industry for transporting chemicals and other corrosive substances at high pressures and temperatures.

Construction industry: It is also used in the construction industry for large-scale infrastructure projects that require large diameter pipelines.

Our Company

Flanges are essential components in any machinery system that requires the transfer of fluids or gases, and Shandong Machinery Co., Ltd is one of the leading manufacturers of flanges in China. Among its top-notch products is the Jin Runyuan flange, one of the company's most outstanding products.

Located in the famous "township of the blacksmith" in Shandong province, the Jin Runyuan flange of Shandong Machinery Co., Ltd is conveniently situated in the Jinan chapter grave area. The street agency headquarters is easily accessible, thanks to the efficient transportation system in the area. The convenient location of the company allows it to cater to the flange needs of clients from different industries across the region.

Shandong Machinery Co., Ltd has been in the manufacturing business for over 20 years, and the company boasts of a top-notch production process that adheres to strict quality control guidelines. The company uses advanced technology to ensure that every product they manufacture meets the highest industry standards. Their manufacturing process is environmentally friendly, and they take great measures to ensure that their operations do not negatively impact the environment.

The Jin Runyuan flange of Shandong Machinery Co., Ltd comes in different types, sizes, and materials to meet the diverse needs of clients from different industries. From stainless steel, carbon steel, alloy steel, and others, the company can manufacture flanges according to the specific requirements of customers. The Jin Runyuan flange is renowned for its high precision, durability, and long service life. The company's state-of-the-art manufacturing process ensures that their flanges are of the highest quality.

In addition to the high-quality products that Shandong Machinery Co., Ltd offers, the company has a team of experienced engineers who work tirelessly to meet the diverse needs of their clients. These professionals work hand in hand with customers to understand their needs and come up with customized solutions to meet their unique requirements. The engineers can provide expert advice on the various types of flanges, their applications, and the most suitable materials to use. This personalized approach ensures that clients get the best products to meet their specific needs.

Shandong Machinery Co., Ltd understands the importance of customer satisfaction, and they strive to provide the best possible experience for their clients. They have established an efficient distribution network that ensures timely delivery of products to customers across the country. The company offers competitive prices, making their products affordable for both small and large businesses.

In conclusion, Shandong Machinery Co., Ltd's Jin Runyuan flange is one of the best in the industry, thanks to the company's commitment to quality and customer satisfaction. The flanges come in a variety of sizes, materials, and types, allowing the company to cater to different clients' unique needs. With an experienced team of engineers, a state-of-the-art production process, and a commitment to reducing the environmental impact of their operations, Shandong Machinery Co., Ltd is a reliable and trustworthy supplier of high-quality flanges.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor