The production process of a 5K 50A flat flange typically involves several steps:

Material selection: The flange is typically made from a durable and corrosion-resistant material such as carbon steel (ASTM A105), stainless steel, or alloy steel. The choice of material depends on the specific application and the required properties of the flange.

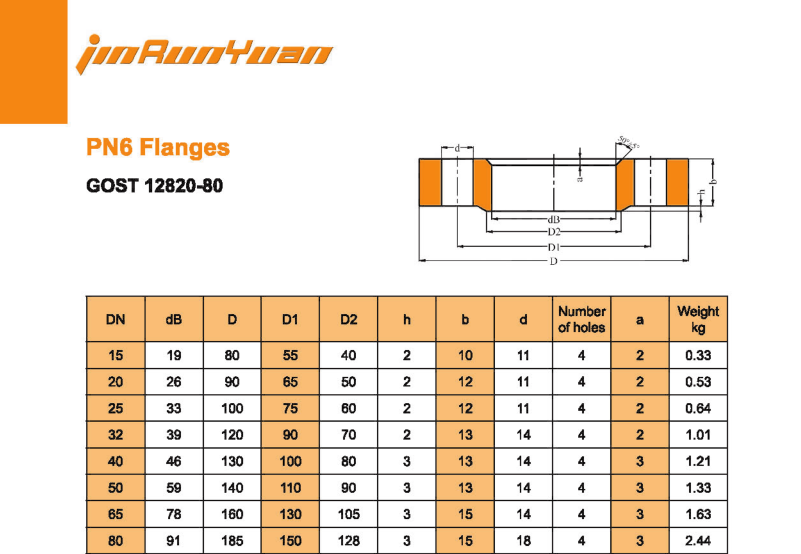

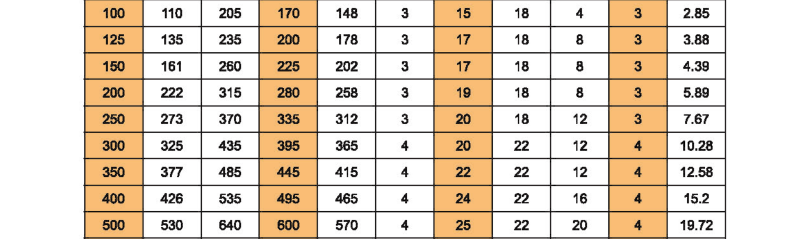

Cutting and shaping: The raw material is cut into the desired shape using cutting tools or by machining processes such as milling or turning. The dimensions of the flange are carefully controlled to ensure proper fit and alignment with the connecting pipes.

Drilling and tapping: The flange is then drilled with bolt holes, usually in a circular arrangement, to accommodate the bolts that will secure it to the connecting pipes. The bolt holes are typically tapped to provide threads for the bolts.

Surface treatment: The flange is often subjected to surface treatments to enhance its corrosion resistance and improve its appearance. Common surface treatments include pickling, passivation, or coating with a protective layer such as galvanization.

Quality control: Throughout the production process, strict quality control measures are implemented to ensure that the flange meets the required specifications and standards. This includes inspections for dimensional accuracy, visual defects, and material integrity.

As for the characteristics of a 5K 50A flat flange, here are some important details:

Size: The "5K" refers to the flange pressure rating, which signifies a pressure class of 5 kilograms per square centimeter. The "50A" refers to the flange nominal size, indicating a nominal diameter of 50 millimeters.

Flat face design: A flat flange has a flat sealing surface, which ensures even distribution of pressure and provides a reliable seal when connected to flat-faced piping components.

Bolt hole configuration: The flange typically has bolt holes drilled in a circular pattern around the flange face. The number and size of the bolt holes may vary depending on the specific flange standards (e.g., JIS B2220 for Japanese flanges).

Application versatility: The 5K 50A flat flange is commonly used in industries such as oil and gas, chemical processing, and water treatment. It is suitable for connecting pipes, valves, fittings, and other equipment in various piping systems.

Pressure rating: The 5K flange is designed to withstand a maximum operating pressure of 5 kilograms per square centimeter (equivalent to 0.49 megapascals or 72 psi).

Temperature range: The flange is typically designed to handle a range of temperatures depending on the material of construction. Carbon steel flanges, for example, can typically handle temperatures ranging from -29°C to 425°C (-20°F to 800°F).

It's important to note that specific dimensions, materials, and standards may vary depending on the manufacturer and the specific project requirements. It is advisable to consult the appropriate flange standards and specifications for accurate and up-to-date information.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor