PN10 DN50 Flat plate Flange

A flat flange is a crucial component in various industrial applications, facilitating the connection between pipes, valves, and

other equipment. Among the wide array of flat flanges available in the market, the PN10 DN50 flat plate flange stands out

as a high-quality option. In this article, we will delve deeper into the features and benefits of this particular flange, focusing

particularly on its galvanized variant in line with Japanese standard flanges.

Firstly, let's explore the PN10 DN50 designation. The PN10 label indicates that the flat plate flange can withstand a pressure

rating of 10 bar, making it suitable for medium-pressure applications. Meanwhile, DN50 signifies that the flange has a

nominal bore size of 50 millimeters, guaranteeing a proper fit for pipes with the same diameter.

One remarkable feature of the PN10 DN50 flat plate flange is its galvanized coating. Galvanizing involves the application of

a protective layer of zinc to the steel body of the flange, enhancing its resistance to corrosion and rust. As a result, the

galvanized flat flange can withstand harsh environmental conditions, making it suitable for both indoor and outdoor

installations. This characteristic particularly suits industries such as construction, water treatment, and oil and gas, where

flanges may be exposed to moisture, chemicals, and varying temperatures.

PN10 DN50 flat flange is a flange used in piping systems. PN10 refers to the pressure rating of the flange, which means that it can withstand a maximum pressure of 10 bar or 145 psi. DN50 indicates the nominal diameter or size of the pipe that the flange will use, which is 50mm. A in place. This type of flange is commonly used in low-pressure applications.

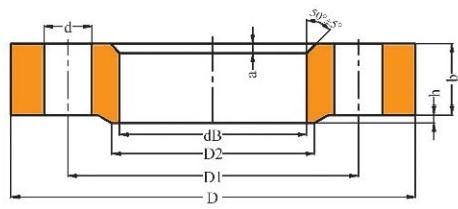

DN | dB | D | D1 | D2 | h | b | d | Number of holes | a | Weight kg |

15 | 19 | 95 | 65 | 47 | 2 | 10 | 14 | 4 | 2 | 0.51 |

20 | 26 | 105 | 75 | 58 | 2 | 12 | 14 | 4 | 2 | 0.74 |

25 | 33 | 115 | 85 | 68 | 2 | 12 | 14 | 4 | 2 | 0.89 |

32 | 39 | 135 | 100 | 78 | 2 | 14 | 18 | 4 | 2 | 1.4 |

40 | 46 | 145 | 110 | 88 | 3 | 15 | 18 | 4 | 3 | 1.71 |

50 | 59 | 160 | 125 | 102 | 3 | 15 | 18 | 4 | 3 | 2.06 |

65 | 78 | 180 | 145 | 122 | 3 | 17 | 18 | 4 | 3 | 2.8 |

80 | 91 | 195 | 160 | 133 | 3 | 17 | 18 | 4 | 3 | 3.19 |

100 | 110 | 215 | 180 | 158 | 3 | 19 | 18 | 8 | 3 | 3.96 |

125 | 135 | 245 | 210 | 184 | 3 | 21 | 18 | 8 | 3 | 5.4 |

150 | 161 | 280 | 240 | 212 | 3 | 21 | 22 | 8 | 3 | 6.62 |

200 | 222 | 335 | 295 | 268 | 3 | 21 | 22 | 8 | 3 | 8.05 |

250 | 273 | 390 | 350 | 320 | 3 | 23 | 22 | 12 | 3 | 10.65 |

300 | 325 | 440 | 400 | 370 | 4 | 24 | 22 | 12 | 4 | 12.9 |

350 | 377 | 500 | 460 | 430 | 4 | 24 | 22 | 16 | 4 | 15.85 |

400 | 426 | 565 | 515 | 482 | 4 | 26 | 26 | 16 | 4 | 21.56 |

500 | 530 | 670 | 620 | 585 | 4 | 28 | 26 | 20 | 4 | 27.7 |

600 | 630 | 780 | 725 | 685 | 5 | 31 | 30 | 24 | 5 | 39.4 |

700 | 720 | 895 | 840 | 800 | 5 | 34 | 30 | 24 | 5 | 59.46 |

800 | 820 | 1010 | 950 | 905 | 5 | 37 | 33 | 24 | 5 | 79.16 |

900 | 920 | 1110 | 1050 | 1005 | 5 | 40 | 33 | 28 | 5 | 94.13 |

1000 | 1020 | 1220 | 1160 | 1110 | 5 | 43 | 33 | 28 | 5 | 118.43 |

1200 | 1222 | 1455 | 1380 | 1330 | 5 | 51 | 39 | 32 | 5 | 197.44 |

1400 | 1420 | 1675 | 1590 | 1530 | 5 | 60 | 45 | 36 | 5 | 278.92 |

1600 | 1620 | 1915 | 1820 | 1750 | 5 | 70 | 52 | 40 | 5 | 422.65 |

Furthermore, the PN10 DN50 flat plate flange adheres to the Japanese standard, which is renowned for its meticulous engineering and stringent quality control.

Japanese standard flanges offer a high degree of precision and reliability, ensuring a secure and leak-free connection. This makes them a preferred choice in

industries that require utmost safety and dependability, such as nuclear power plants, aerospace, and automotive manufacturing.

The PN10 DN50 flat plate flange in the galvanized variant combines the best of both worlds—excellent corrosion resistance as well as adherence to the superior

Japanese standard. This amalgamation makes it a perfect option for a myriad of applications where durability and performance are paramount. Additionally, the

galvanized coating adds an aesthetic appeal to the flange, making it visually appealing and suitable for architectural purposes.