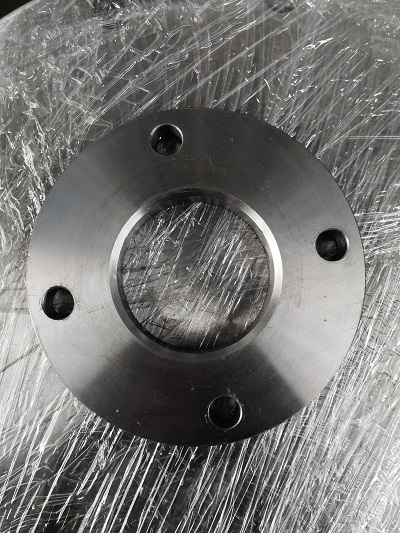

PN10 DN80 Flat Flange

A New Flange Design Revolutionizes High-Pressure and High/Low Temperature Functions

In a breakthrough that could revolutionize high-pressure and high/low temperature functions, a new flange design has been introduced. This innovative flange type, normally used in applications that require an unrestricted flow of fluids through piping systems, promises to eliminate issues such as turbulence, erosion, and corrosion of metals in the vicinity of flanged joints.

The key feature of this flange design lies in its bore, which perfectly aligns with the bore of the pipe it is attached to. This alignment ensures a seamless flow of fluid, without any strain drops. By minimizing strain drops, this new flange prevents the occurrence of unwanted turbulence, which can have detrimental effects on the overall performance of the piping system. Turbulence not only reduces the efficiency of fluid flow but can also lead to erosion and corrosion of the metals used in the flanged joints.

One of the critical components of this flange design is its tapered hub. The tapered hub plays a significant role in distributing mechanical stress evenly between the pipe and the weld neck flange. This even distribution of stress helps in maintaining the integrity and longevity of the piping system. By reducing stress concentrations, this flange design minimizes the chances of failure and enhances the overall performance of the system.

The benefits of this new flange design extend beyond improved performance and reduced maintenance. This innovative design could potentially bring cost benefits to industries that rely on high-pressure and high/low temperature functions. By preventing erosion, corrosion, and turbulent flow, companies can avoid costly repairs, replacements, and downtime. Additionally, the longevity and efficiency of the system can lead to enhanced productivity, further boosting the profitability of businesses.

Experts in the field are lauding this flange design as a game-changer. They believe that this unique design has the potential to transform various industries, including oil and gas, petrochemicals, power generation, and beyond. The introduction of this flange design is expected to set new industry standards, encouraging other manufacturers to develop similar products, further driving innovation in the field.

Amidst growing concerns about sustainability and environmental impact, this flange design also holds promise. By ensuring a smooth flow of fluid and eliminating turbulence, the energy efficiency of the system can be significantly improved. This, in turn, reduces energy consumption, minimizing the carbon footprint of industries that rely on high-pressure and high/low temperature functions.

While the exact details of this new flange design are yet to be disclosed, industry insiders are eagerly awaiting its commercial availability. Manufacturers and end-users alike are recognizing the potential of this innovation to revolutionize their operations, enhance performance, reduce costs, and contribute to a more sustainable future. As this technology is adopted in a wide range of applications, its impact on industries around the world is expected to be significant.

PN10 refers to the pressure rating for the flange, which is 10 bar (145 psi). DN80 refers to the nominal diameter of the pipe that the flange is designed to connect to, which is 80 mm (approximately 3 inches). Flat Flange means that the surface of the flange is flat.

Advantages of PN10 DN80 Flat flange:

High Pressure Rating: PN10 DN80 flat flange has a high pressure rating of 10 bar making it suitable for high-pressure applications where the pressure is high up to 145 psi.

Easy Assembly: These flanges can be easily assembled with a simple gasket and bolt arrangement.

Versatility: PN10 DN80 flat flanges are versatile and can be used in a wide range of industrial applications including in chemical, petrochemical, oil and gas, pharmaceuticals, and water treatment plants.

Cost-effective: These flanges are cost-effective and can be easily replaced if damaged over time.

Applications of PN10 DN80 Flat Flange:

Chemical processing: PN10 DN80 Flat Flange finds its application in the chemical processing industry where the chemical material is corrosive and needs a flange that can withstand high pressure and temperature.

Water Treatment: PN10 DN80 Flat flanges are extensively used in water treatment plants for the installation of pumps, pipelines, and other equipment.

Petrochemical industry: These flanges are utilized in the petrochemical industry for connecting pipelines to pumps and valves.

Pharmaceutical industry: PN10 DN80 Flat flanges are used in the pharmaceutical industry for the production of drugs, where high levels of sanitation and cleanliness are required.

Oil and gas industry: In the oil and gas industry, these flanges are used to connect pipelines and valves, as well as at pumping stations.

Our Company

Jin Runyuan flange of Shandong Machinery CO., LTD, located in the renowned "township of the blacksmith", Shandong Jinan chapter grave area, is a leading manufacturer of forging flanges. Our company, established in 2001, boasts an expansive area of 20,000 square meters, providing us with the necessary space to carry out our manufacturing processes effectively.

As a professional manufacturer, we prioritize quality and customer satisfaction. We offer a wide range of products, including Japanese standard, American standard, and German standard flanges. Additionally, we can also customize flanges to meet the specific requirements of our customers, as per their drawings or samples.

Our flanges are meticulously crafted using state-of-the-art technology and machinery. With a highly skilled workforce and a team of experienced engineers, we ensure that each flange meets the highest industry standards. Our commitment to quality extends to the materials we use. We source the finest materials to guarantee the durability and reliability of our products.

One of our key strengths is the convenience we offer in terms of transportation. Situated in an area with convenient access to major transportation networks, our headquarters embody our dedication to efficient logistics. This allows us to promptly deliver flanges to our customers, regardless of their location.

Furthermore, our location in the picturesque Shandong Jinan chapter grave area provides us with a beautiful environment that inspires us to maintain sustainable manufacturing practices. We strive to minimize our impact on the environment by implementing eco-friendly measures throughout our production processes. We are committed to conserving resources and reducing waste, ensuring that our operations align with global sustainability goals.

At Jin Runyuan Flange, we believe in building strong relationships with our customers. Our team of dedicated professionals is always ready to assist you with any inquiries or requirements you may have. We also prioritize after-sales service, offering technical support and guidance to ensure the optimal performance of our flanges.

In conclusion, Jin Runyuan flange of Shandong Machinery CO., LTD is a trusted manufacturer of high-quality flanges. With our extensive range of products, customization options, commitment to quality, and focus on customer satisfaction, we aim to be your preferred partner for all your flange needs. Trust in our expertise and choose Jin Runyuan flange for reliable, durable, and efficient solutions.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor