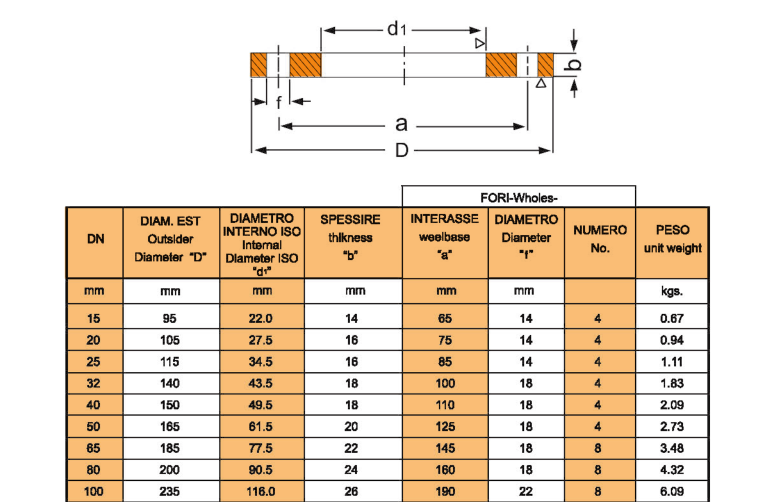

PN16 DN150 Flat Flange

Title: Weld Neck Flange Enables Efficient Fluid Flow and Prevents Metal Erosion and Corrosion

In high-pressure and high/low temperature applications, a specific type of flange known as the weld neck flange is crucial. This flange is designed to facilitate an unrestricted flow of fluid through the piping device, ensuring efficient operations and preventing adverse effects such as turbulence and erosion/corrosion of metals near the flanged joints.

The weld neck flange is specifically developed to fit perfectly with the bore of the pipe, significantly reducing strain drops. The absence of such drops not only ensures a smooth flow of the fluid but also prevents potential drawbacks that can arise due to turbulence and erosion/corrosion of the metals near the flange joints.

One notable feature of the weld neck flange is its tapered hub. This design allows for the distribution of mechanical stress between the pipe and the flange, ensuring optimal stability and load-bearing capacity. By evenly distributing the stress, this flange type effectively reduces the risk of failure or leaks at the joints.

The weld neck flange is commonly used in various industries, including oil and gas, chemical, and petrochemical. These sectors often operate under extreme conditions, involving high-pressure and high/low temperature environments. In such settings, the weld neck flange guarantees the reliability and safety of the piping systems.

One of the key advantages of weld neck flanges is their ability to reinforce the strength of the joint. The welding process permanently bonds the pipe to the flange, eliminating the likelihood of separation or leaks. This makes them suitable for applications where the pipeline's integrity must be maintained, and fluid leakage is not acceptable.

Furthermore, the weld neck flange offers enhanced durability and resistance to deformation and stress, making it highly reliable in critical applications. Its robust design ensures that it can withstand the severe conditions that may arise in high-pressure or high/low temperature operations.

The efficient distribution of stress achieved through the tapered hub design not only prolongs the lifespan of the flanged joints but also minimizes the maintenance requirements and associated costs. By reducing strain and preventing metal erosion and corrosion, the weld neck flange significantly extends the lifespan of the entire piping system.

Overall, the weld neck flange is an indispensable component in high-pressure and high/low-temperature applications that demand unrestricted fluid flow and durability. Its ability to distribute mechanical stress evenly and prevent turbulence, erosion, and corrosion makes it a reliable and cost-effective solution for various industries.

As technology advances and industries continue to face challenging operating conditions, the weld neck flange will continue to play a vital role in ensuring efficient fluid conveyance and maintaining the integrity of the piping systems.

PN16 DN150 flat flange typically refers to a standard size flange used for pipes with a diameter of 150mm and designed to be used in applications with a pressure rating of 16 bar. It has a flat sealing surface and is typically bolted to other flanges using bolts and nuts. The PN16 rating indicates the maximum allowable pressure the flange can handle without failure.

Advantages:

Strong and durable: PN16 DN150 flat flanges are usually made of high-quality materials such as stainless steel, carbon steel, and alloy steel, making them strong and durable.

Compatible: They can be used with a wide range of pipes, fittings, and valves, making them versatile.

Applications:

PN16 DN150 flat flanges are commonly used in waste water treatment plants, water supply systems, and chemical processing plants.

They can be used in pipelines for gas, oil, and steam transmission.

They are used in industries such as construction, mining, and pharmaceuticals.

They are also utilized in food and beverage processing, as well as in heating and ventilation systems.

Our Company

Jin Runyuan flange of Shandong Machinery CO., LTD is located in the famous "township of the blacksmith"-Shandong Jinan chapter grave area set street agency headquarters, where convenient transportation beautiful environment. Company was founded in 2001, covers an area of 20000 square meters, is a professional manufacturer of forging flange company, main products: Japanese standard, American standard, German standard, the standard also can according to customers drawings or samples processing. Existing fixed assets of 40 million,the annual output 40 million tons.Products are exported to Japan, the United States, Germany, South Korea, Russia, Brazil, South Africa, more than 20 countries and regions, such as product quality deeply the general customers the high praise and trust.

Company strong technical force, professional experience, equiptment, professional production and technical personnel 10 people, the production of 120 front-line workers, management personnel E people, packing, inspection personnel more than 20 people. High quality international most advanced forging machinery processing, assembly, inspection, packaging production lines, product quality meet the national and international standards, and has obtained ISSO9001-2000 quality management system certification, the French classification society certification, China special equipment manufacturing license, pressure vessel manufacturing license.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor