PN16 DN250 Flat flange

Flange, moreover regarded as flange or flange. It is the segment that connects pipes to pipes. Connected to tube end. There are holes on the flange, and bolts can be worn to make the two flanges tightly connected. The flanges are gasketed. Flanged pipe fittings are pipe fittings with flanges (flanges or joints). It can be cast, threaded or welded. flange joints (flange, joint) are usual of a pair of flanges, a gasket, and severa bolts and nuts. The gasket is placed between the sealing ground of the two flanges. After tightening the nut, the particular pressure on the flooring of the gasket will be deformed after accomplishing a positive value, and the uneven part of the sealing flooring will be filled, so that the connection is tight and no longer leaking. Some pipe fittings and tools have their very personal flange, moreover belong to the flange connection. Flange connection is an vital connection mode in pipeline construction.

Flange connection is available to use and can face up to large pressure. Flange connection is notably used in industrial pipeline. In the home, the pipe diameter is small, and is low pressure, no longer viewed flange connection. If you are in a boiler room or a manufacturing site, there are flanged pipes and tools everywhere.

The motive of the flange is to tightly closed and seal the joint of the pipe fitting. Flange is usually used to be a part of tight pipes, pipe fittings, etc., and hold the sealing general overall performance of pipe fittings; Flange detachable, handy to disassemble take a appear at pipe condition. Reducing flange corrosion resistance, acid and alkali resistance, can be used in water conservancy, electric powered powered power, power station, pipeline fittings, industry, stress vessels and distinct aspects.

Stainless metallic flange can be used for boiler stress vessels, petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, ingredients and exceptional industries, it is handy to alternative a section of pipeline.

Advantages of PN16 DN250 flat flange:

Versatility: PN16 DN250 Flat Flange is like minded with a range of pipes, fittings, and equipment, making it a versatile preference in more than a few industries.

Easy installation: The flat flange format permits for effortless set up and removal, decreasing downtime and labor costs.

Pressure rating: PN16 (16 bar) suggests the most strain the flange can withstand, making it appropriate for purposes that require average stress handling.

Leak-proof connection: When exact set up with a gasket, PN16 DN250 flat flange offers a dependable and leak-proof connection, making sure the integrity of the piping system.

Cost-effective: Flat flanges are normally extra reasonably-priced in contrast to different sorts of flanges, making them a famous preference in many industries.

Characteristics of PN16 DN250 Flat Flange:

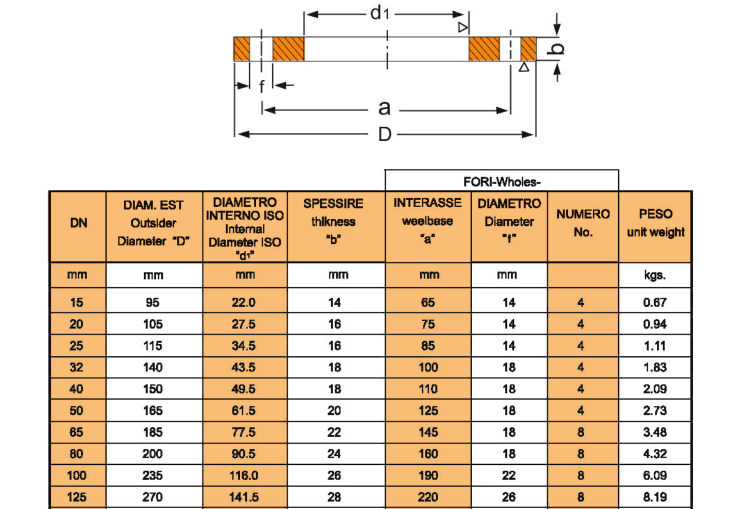

Size: DN250 refers to the nominal diameter of the pipe that the flat flange can accommodate. In this case, it can match pipes with a diameter of 250mm.

Flat surface: The flat flange has a smooth, flat floor barring any raised edges or grooves, permitting for a uniform distribution of stress and handy sealing.

Material: PN16 DN250 flat flanges are normally made from substances like carbon steel, stainless steel, or alloy steels, relying on the unique necessities of the application.

Bolts and Holes: The flange normally comes with bolt holes for connecting it to the corresponding piping or equipment. The wide variety and measurement of the bolt holes rely on the flange widespread and pipe size.

Standards: PN16 DN250 flat flanges are manufactured in accordance to more than a few enterprise standards, which includes DIN, EN, ANSI/ASME, and JIS, amongst others.

Production Process of PN16 DN250 Flat Flange:

The manufacturing system of PN16 DN250 flat flange normally includes the following steps:

Material selection: The suitable material, such as carbon metal or stainless steel, is chosen primarily based on the working prerequisites and necessities of the application.

Cutting and shaping: The raw fabric is reduce and fashioned to the favored dimension and form the usage of slicing tools, machining, or casting processes.

Machining the flat surface: The flange floor is machined to gain a easy and flat surface, making sure a suitable sealing surface.

Drilling bolt holes: Holes are drilled into the flange for bolt connections, following the distinctive dimensions and standards.

Testing and first-rate control: The completed flanges bear a number tests, together with strain testing, dimensional inspection, and visible inspection, to make certain they meet the required pleasant standards.

Surface treatment: Depending on the fabric and unique requirements, the flanges may additionally endure floor redress such as painting, galvanizing, or coating to enhance corrosion resistance.

Packaging and shipment: Finally, the flanges are packaged for safety at some point of transportation and shipped to the clients or storage facility.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor