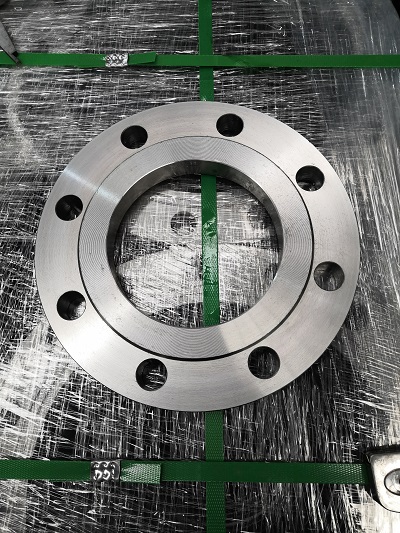

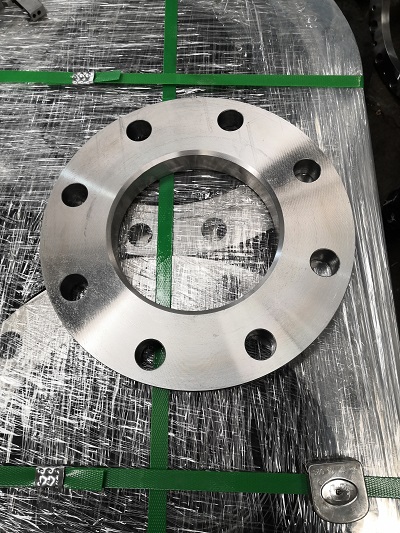

PN25 DN150 Flat Flange

Flange, in addition considered as flange or flange. It is the phase that connects pipes to pipes. Connected to tube end. There are holes on the flange, and bolts can be worn to make the two flanges tightly connected. The flanges are gasketed. Flanged pipe fittings are pipe fittings with flanges (flanges or joints). It can be cast, threaded or welded. flange joints (flange, joint) are regular of a pair of flanges, a gasket, and severa bolts and nuts. The gasket is positioned between the sealing floor of the two flanges. After tightening the nut, the unique stress on the ground of the gasket will be deformed after carrying out a tremendous value, and the uneven section of the sealing ground will be filled, so that the connection is tight and no longer leaking. Some pipe fittings and equipment have their very non-public flange, in addition belong to the flange connection. Flange connection is an necessary connection mode in pipeline construction.

Flange connection is handy to use and can face up to giant pressure. Flange connection is especially used in industrial pipeline. In the home, the pipe diameter is small, and is low pressure, no longer seen flange connection. If you are in a boiler room or a manufacturing site, there are flanged pipes and equipment everywhere.

The purpose of the flange is to tightly closed and seal the joint of the pipe fitting. Flange is typically used to be a phase of tight pipes, pipe fittings, etc., and keep the sealing usual normal overall performance of pipe fittings; Flange detachable, reachable to disassemble take a show up at pipe condition. Reducing flange corrosion resistance, acid and alkali resistance, can be used in water conservancy, electric powered powered powered power, strength station, pipeline fittings, industry, stress vessels and awesome aspects.

Stainless steel flange can be used for boiler stress vessels, petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, elements and incredible industries, it is available to choice a area of pipeline.convenient to disassemble take a appear at pipe condition. Reducing flange corrosion resistance, acid and alkali resistance, can be used in water conservancy, electric powered powered power, power station, pipeline fittings, industry, pressure vessels and specific aspects.

Stainless steel flange can be used for boiler stress vessels, petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, foods and unique industries, it is handy to alternative a section of pipeline.

The manufacturing manner for PN25 DN150 flat flanges generally includes the following steps:

Material selection: Flanges are usually made from substances such as carbon steel, stainless steel, or alloy steel. The chosen cloth will rely on elements such as the application, strain rating, and corrosion resistance requirements.

Cutting: The uncooked cloth is reduce into fantastic sizes for the DN150 flanges the usage of reducing methods such as sawing or shearing.

Forming: The reduce fabric is then heated and shaped into flat flanges the use of tactics such as forging or rolling. This step ensures that the flanges have the required structure and dimensions.

Machining: The shaped flanges bear machining approaches such as drilling, milling, and turning to attain easy surfaces and correct dimensions. This step may additionally additionally contain threading or grooving if necessary.

Surface treatment: The flanges are cleaned and organized for floor treatment, which can encompass methods like shot blasting or sandblasting to put off any impurities or difficult surfaces. This is observed by way of a shielding coating or plating to decorate corrosion resistance.

Quality control: Flanges endure strict great manipulate procedures to make certain they meet the required requirements and specifications. This may also contain dimensional inspections, stress testing, and fabric testing.

Features of PN25 DN150 flat flanges:

Pressure rating: PN25 suggests that the flanges are designed to cope with working pressures up to 25 bar. This makes them appropriate for functions that require greater stress managing capabilities.

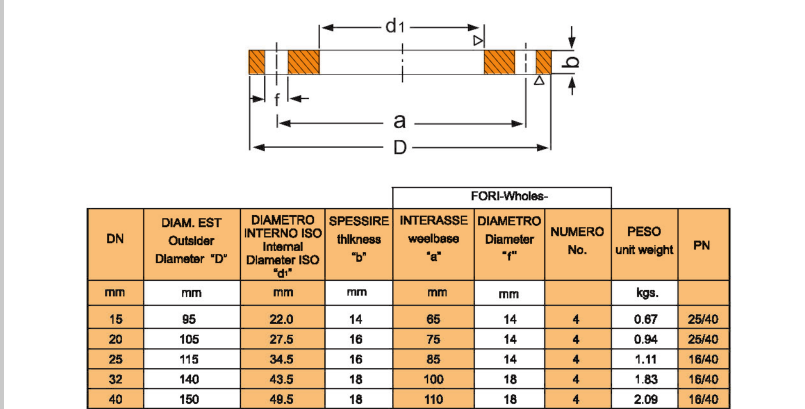

Size: DN150 denotes the nominal pipe size, indicating that the flanges are designed to match pipes with a diameter of a hundred and fifty mm.

Flat face: Flat flanges have a flat sealing surface, which affords a giant contact vicinity for fine sealing. This makes them appropriate for purposes the place sealing is crucial, such as in pipelines or gear connections.

Easy installation: Flat flanges are surprisingly handy to deploy and align due to their easy design. This can shop time and effort at some stage in set up or protection tasks.

Versatility: Flat flanges can be used in a vast vary of industries and applications, which include oil and gas, chemical processing, water treatment, and strength generation.

Compatibility: DN150 flat flanges are designed to be well suited with pipes or fittings of the equal measurement and strain rating, permitting for convenient connection and compatibility with present systems.

PN25 DN150 flat face flange is a type of flange used in piping systems that has a pressure rating of PN25 which means it can withstand a maximum pressure of 25 bar or 362.5 psi. DN150 indicates the nominal diameter or size of the pipe the flange will be used in, which is 150 mm. This flat flange has a flat sealing surface and bolts pass through the flange to hold it in place. This type of flange is typically used in high-pressure applications where the fluid being conveyed requires a stronger, more durable connection.