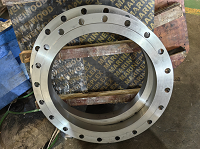

PN10 DN600 Weld Neck Flange

Flange, in addition considered as flange or flange. It is the phase that connects pipes to pipes. Connected to tube end. There are holes on the flange, and bolts can be worn to make the two flanges tightly connected. The flanges are gasketed. Flanged pipe fittings are pipe fittings with flanges (flanges or joints). It can be cast, threaded or welded. flange joints (flange, joint) are normal of a pair of flanges, a gasket, and severa bolts and nuts. The gasket is located between the sealing floor of the two flanges. After tightening the nut, the unique stress on the ground of the gasket will be deformed after carrying out a superb value, and the uneven section of the sealing ground will be filled, so that the connection is tight and no longer leaking. Some pipe fittings and tools have their very personal flange, in addition belong to the flange connection. Flange connection is an vital connection mode in pipeline construction.

Flange connection is available to use and can face up to giant pressure. Flange connection is particularly used in industrial pipeline. In the home, the pipe diameter is small, and is low pressure, no longer seen flange connection. If you are in a boiler room or a manufacturing site, there are flanged pipes and tools everywhere.

The reason of the flange is to tightly closed and seal the joint of the pipe fitting. Flange is usually used to be a phase of tight pipes, pipe fittings, etc., and keep the sealing ordinary regular basic performance of pipe fittings; Flange detachable, reachable to disassemble take a exhibit up at pipe condition. Reducing flange corrosion resistance, acid and alkali resistance, can be used in water conservancy, electric powered powered powered powered power, power station, pipeline fittings, industry, stress vessels and superb aspects.

Stainless steel flange can be used for boiler stress vessels, petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, elements and excellent industries, it is available to choice a area of pipeline.convenient to disassemble take a appear at pipe condition. Reducing flange corrosion resistance, acid and alkali resistance, can be used in water conservancy, electric powered powered powered power, power station, pipeline fittings, industry, pressure vessels and specific aspects.

Stainless steel flange can be used for boiler stress vessels, petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, ingredients and unique industries, it is on hand to choice a section of pipeline.

PN10 DN600 WeldNeck Flanges have several advantages and characteristics.

Pressure Rating:Advantages of PN10 DN600 WeldNeck Flanges:

High Pressure Resistance: PN10 rating implies that these flanges can withstand a maximum operating pressure of 10 bar, making them suitable for high-pressure applications.

Increased Safety: WeldNeck flanges have a long tapered hub that provides excellent reinforcement and reduces the risk of leakage or failure under high-pressure conditions.

Improved Fluid Flow: The smooth transition from the flange to the pipe reduces turbulence and pressure drop, ensuring efficient fluid flow.

Enhanced Strength: These flanges are designed to withstand high mechanical stress and vibration, making them suitable for demanding industrial environments.

Easy Alignment: The Neck of the WeldNeck flanges allows easy alignment of the pipes during installation, ensuring a secure and leak-free connection.

Durability: PN10 DN600 WeldNeck Flanges are typically made of sturdy materials such as carbon steel, stainless steel, or alloy steel, ensuring long-lasting performance in corrosive or high-temperature environments.

Versatility: WeldNeck flanges can be used in a wide range of industries, including petrochemical, oil and gas, water treatment, and power generation, due to their compatibility with various pipes and applications.

Production Process of PN10 DN600 WeldNeck Flanges:

Material Selection: Suitable materials like carbon steel, stainless steel, or alloy steel are chosen based on the application requirements.

Cutting: The chosen material is cut into the required dimensions, taking into account the flange's diameter, thickness, and neck length specifications.

Forming: The cut material is then heated and shaped into the desired flange shape using a forging or casting process. The welding neck is carefully shaped to ensure proper alignment and strength.

Machining: After forming, the rough flange is machined to achieve precise dimensions and smooth surface finish. This involves processes like turning, milling, boring, and drilling.

Drilling Bolt Holes: Holes are drilled into the flange to accommodate the bolts that will connect it to the mating flange or pipe.

Surface Treatment: The flange undergoes surface treatment processes like pickling, passivation, or galvanization to enhance its corrosion resistance properties.

Quality Inspection: The finished flange is thoroughly inspected for dimensional accuracy, welding quality, and surface finish to ensure it meets the required standards andAdvantages of PN10 DN600 WeldNeck Flanges:

High pressure and temperature resistance: PN10 denotes a pressure rating of 10 bar, indicating that these flanges can withstand high-pressure conditions.

Durable and long-lasting: WeldNeck flanges provide a strong and secure connection, minimizing the risk of leakage or failure.

Easy installation: These flanges are designed with a tapered neck that helps guide the pipe into position, making installation easier.

Suitable for high-stress applications: WeldNeck flanges are commonly used in industries such as oil and gas, chemical, and petrochemical, where high-stress conditions are prevalent.

Versatile connection options: WeldNeck flanges allow for easy connection to pipes or other components, using welding processes, making them suitable for a wide range of applications.

Characteristics of PN10 DN600 WeldNeck Flanges:

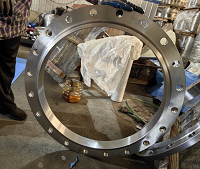

Size: DN600 indicates the nominal diameter of the flange, which is 600mm. This size can accommodate pipes with a corresponding outer diameter.

Pressure rating: The PN10 designation signifies a pressure rating of up to 10 bar, meaning these flanges can handle medium to high-pressure applications.

Flange face type: PN10 DN600 WeldNeck flanges typically feature a raised face or flat face, depending on the specific requirements.

Material: These flanges are often made from durable and corrosion-resistant materials such as stainless steel, carbon steel, or alloy steel, depending on the application.

Welding requirements: As the name suggests, WeldNeck flanges are designed for welding connections. They require welding processes like TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding for secure attachment.

Production Process of PN10 DN600 WeldNeck Flanges:

Material selection: Suitable material is chosen based on the specific requirements of the application, considering factors such as temperature, pressure, and corrosion resistance.

Cutting and shaping: The selected material is cut into the required shape using machines such as shears, saws, or plasma cutters.

Forming the flange: The cut material is then molded or forged into the appropriate shape using tools or machines like hydraulic presses or forging hammers.

Machining: The flange may undergo machining processes like turning, milling, or drilling to achieve the desired dimensions and surface finish.

Welding preparation: The flange is then prepared for welding by cleaning, beveling, and aligning the weld surfaces.

Welding: The flange is attached to the pipe or component using welding techniques such as TIG or MIG welding, ensuring a strong and secure connection.

Inspection and testing: The finished weldneck flange undergoes thorough inspection and testing to ensure it meets theAdvantages of PN10 DN600 WeldNeck Flanges:

High Pressure Rating: PN10 DN600 WeldNeck Flanges are designed to withstand a pressure rating of up to PN10, which translates to a maximum pressure of 10 bar or 145 psi. This makes them suitable for applications involving high-pressure fluids or gases.

Easy Installation: WeldNeck Flanges are designed with a tapered hub, allowing for easy alignment and welding to the adjoining pipes. This ensures a secure and leak-free connection.

Enhanced Strength and Durability: These flanges are manufactured using high-quality materials such as carbon steel or stainless steel, ensuring excellent strength and durability. This makes them suitable for a wide range of industrial applications.

Reliable Sealing: PN10 DN600 WeldNeck Flanges come with a machined sealing surface, which, when mated with a compatible gasket, ensures a reliable seal. This prevents leakage and guarantees the integrity of the pipeline system.

Characteristics of PN10 DN600 WeldNeck Flanges:

Dimensional Standards: PN10 DN600 WeldNeck Flanges are manufactured according to industry-standard dimensional specifications, such as DIN, ANSI, or EN. These standards ensure compatibility and interchangeability.

Pipe Compatibility: DN600 refers to the nominal size of the pipe for which the flange is designed. DN600 flanges are suitable for pipes with an outer diameter of approximately 273.1mm (10.75 inches).

Welding Method: These flanges are specifically designed for welding to the adjoining pipe. The flange hub has a beveled end, allowing for a smooth transition and ease of welding.

Raised Face: PN10 DN600 WeldNeck Flanges typically come with a raised face on the flange surface, which provides additional rigidity and allows for easy identification and alignment during installation.

Production Process of PN10 DN600 WeldNeck Flanges:

Material Selection: The production process begins with the selection of high-quality materials, such as carbon steel or stainless steel, based on the specific requirements of the application.

Cutting and Shaping: The raw material is then cut and shaped into the desired dimensions using cutting tools and machining processes, ensuring accuracy and precision.

Machining: The flange is machined to the required specifications, including the bore size, bolt hole pattern, and flange face finish. This ensures proper alignment and compatibility with the adjoining pipes.

Welding: The flange hub is welded to the pipe using suitable welding techniques, such as TIG or MIG welding. This creates a strong and secure connection that can withstand high-pressure applications.

Surface Treatment: The flange is subjected to surface treatment processes, such as sandblasting or pickling, to remove any impurities and improve the overall appearance and corrosion resistance.

Quality Control: The finished flanges undergo stringent quality control checks to ensure dimensional accuracy, proper alignment, and adherence to industry standards. They are also tested for leak resistance and pressure rating.

Packaging and Delivery: Finally, the flanges are carefully packaged to prevent damage during transportation and delivered to the customers, ready for installation in their respective applications.

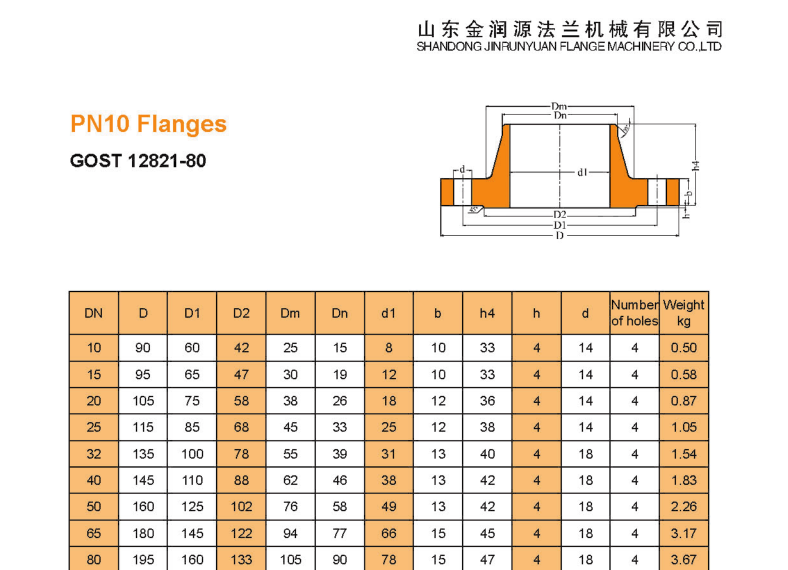

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor