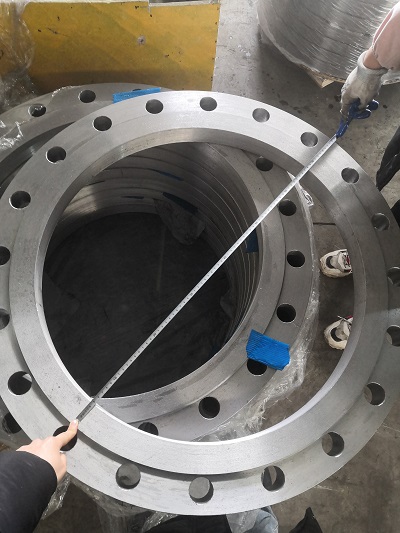

PN25 DN600 Weld Neck Flanges

Flange: Connecting Pipes with Precision

If you own or work in a facility that involves transportation of fluids or gases using pipes, you must have heard the term flange. A flange is an essential segment that helps connect pipes to other pipes or equipment. It plays a significant role in preventing leaks, providing structural strength, and easing maintenance. In this article, we will dive deep into the world of flanges and their importance in various industries.

A flange is a flat or raised circular segment that connects two pipes or equipment. It is connected to the end of a tube and secured using bolts. There are several types of flanges used in the industry, including slip-on flanges, weld-neck flanges, threaded flanges, socket weld flanges, blind flanges, and lap joint flanges. Each flange type has a different connection method, making it suitable for specific applications.

Apart from connecting pipes, flanges also act as a reinforcement mechanism. Since pipes transport high-pressure fluids or gases, flanges ensure that the connection points do not fail due to excess pressure. They provide structural support to the pipes and other equipment and help distribute the weight evenly. Additionally, flanges act as a sealing mechanism that prevents fluid or gas leakage, reducing the risk of accidents and damage.

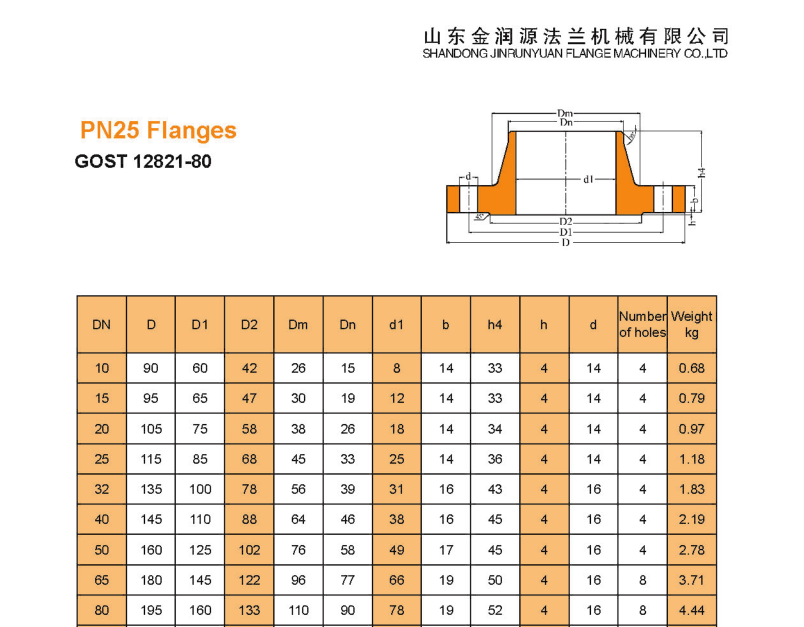

One critical aspect of flanges is the presence of holes on them. These holes are designed to accommodate bolts, which secure the two flanges together. Depending on the flange type, the number and size of the holes may vary. Bolts help create a tight and secure joint and prevent any leaks or failures. The flange-bolt system is essential for maintaining the integrity and safety of the piping system.

Flanges are used in various industries, including oil and gas, chemical, and pharmaceuticals. In the oil and gas industry, high-pressure pipelines use flanges to ensure safe and efficient transportation of fluids. The chemical and pharmaceutical industries use flanges to transport highly reactive or corrosive solutions, and the automotive industry uses them in exhaust systems.

In conclusion, flanges are an essential segment in any pipe or equipment that requires proper connection. They provide structural support, prevent leaks, and ease maintenance. The presence of holes and bolts ensures that the connection is secure, and the flange-bolt system provides a tight and safe joint. Flanges are widely used in various industries, including oil and gas, chemical, and automotive, making them crucial for the smooth functioning of these industries. Next time you encounter a pipe system, remember the crucial role of flanges in keeping the fluids and gases flowing safely and efficiently.

PN25 (Pressure Nominal 25) refers to a flange with a pressure rating of 25 bar. DN600 (Diameter Nominal 600) is the nominal diameter of the flange, in this case, it is 600mm. Weld Neck Flanges are a type of flange used to join pipe to a pressure vessel or valve. They are typically welded to the pipe and provide a metal-to-metal seal with the vessel. Weld Neck Flanges are commonly used in high-pressure applications because of their strength and ability to withstand high pressures and temperatures.

Some benefits of PN25 DN600 Weld Neck Flanges include:

High-pressure resistance: Weld Neck Flanges can withstand very high pressures and temperatures, making them ideal for use in industrial and commercial applications.

Durability: These flanges are made from high-quality materials such as stainless steel or carbon steel, which makes them very durable and corrosion-resistant.

Easy installation: Weld Neck Flanges are easy to install because they can be welded directly onto pipes, valves, or vessels.

Better sealing: The design of the Weld Neck Flange allows for better sealing and eliminates the risk of leaks.

Applications of PN25 DN600 Weld Neck Flanges include but are not limited to:

Oil and Gas industry: These flanges are commonly used in the oil and gas industry for their ability to withstand high pressure and temperature conditions.

Chemical industry: Chemical plants use these flanges to connect pipes, valves, and vessels in their production processes.

Power generation: In power plants, Weld Neck Flanges are used to connect pipes and valves in steam and gas turbines.

Water treatment: Water treatment plants often use these flanges to connect pipes, pumps, and tanks in their system.

Our Company

Jin Runyuan flange of Shandong Machinery CO., LTD is located in the famous "township of the blacksmith"-Shandong Jinan chapter grave area set street agency headquarters, where convenient transportation beautiful environment. Company was founded in 2001, covers an area of 20000 square meters, is a professional manufacturer of forging flange company, main products: Japanese standard, American standard, German standard, the standard also can according to customers drawings or samples processing. Existing fixed assets of 40 million,the annual output 40 million tons.Products are exported to Japan, the United States, Germany, South Korea, Russia, Brazil, South Africa, more than 20 countries and regions, such as product quality deeply the general customers the high praise and trust.

Company strong technical force, professional experience, equiptment, professional production and technical personnel 10 people, the production of 120 front-line workers, management personnel E people, packing, inspection personnel more than 20 people. High quality international most advanced forging machinery processing, assembly, inspection, packaging production lines, product quality meet the national and international standards, and has obtained ISSO9001-2000 quality management system certification, the French classification society certification, China special equipment manufacturing license, pressure vessel manufacturing license.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor