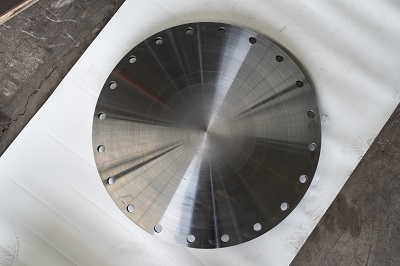

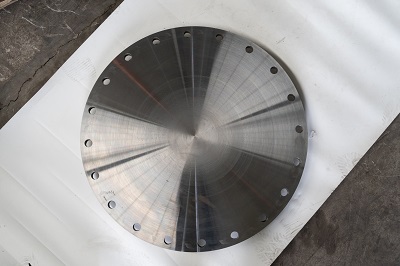

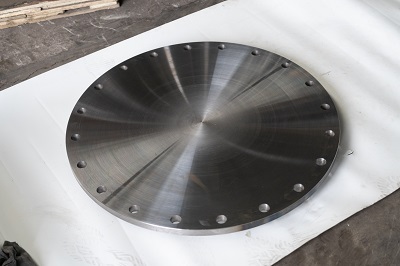

PN25 DN600 Blind Flanges

A blind flange, additionally known as blind flange, is a structure of connection flange that serves a crucial purpose in various industries. Also commonly referred to as a blank flange, its actual title is blind flange, which accurately reflects its function and design. This unique type of flange is essentially a standard flange with a conspicuous feature – a gap in the middle.

One of the most notable features of a blind flange is its ability to close off the end of a pipe or vessel. This feature makes it ideal for applications where the end of a pipeline needs to be sealed shut to prevent leakage or contamination. By securely covering the opening, a blind flange provides a reliable barrier and ensures the integrity and safety of the system.

Blind flanges are widely used in industries such as oil and gas, chemical, petrochemical, and manufacturing. In oil and gas refineries, these flanges are used to seal the ends of pipes, valves, and vessels, preventing the escape of hazardous or volatile substances. They are also employed in chemical plants to isolate sections of pipelines during maintenance or shut-downs.

While blind flanges are mainly utilized for their sealing capabilities, they also offer additional benefits. One of these advantages is their versatility in terms of pressure ratings. Blind flanges can be designed to withstand high-pressure environments, making them suitable for applications that demand a robust sealing solution.

Moreover, blind flanges can be fabricated from a variety of materials to suit specific requirements. Common materials include carbon steel, stainless steel, and alloy steel. The choice of material depends on factors such as chemical compatibility, temperature, and pressure. This versatility enables blind flanges to be employed in a wide range of operating conditions.

Installation of blind flanges is relatively simple and straightforward. The flange is placed over the end of the pipe and secured using bolts. The gap in the middle of the blind flange remains tightly closed, ensuring a complete seal. Additionally, blind flanges can be easily removed and replaced when necessary, providing ease of access for inspections or repairs.

In conclusion, blind flanges play a vital role in various industries by effectively sealing the ends of pipelines and vessels. These flanges, also known as blank flanges, offer a reliable and versatile solution for closing off pipes and preventing leakage or contamination. With their ability to withstand high-pressure environments and compatibility with various materials, blind flanges provide an essential component in the safe and efficient operation of many industrial systems.

A PN25 blind flange with DN600 size would have the following specifications:

PN25 refers to the pressure rating of the flange, which in this case is 25 bar.

DN600 refers to the nominal diameter of the flange, which is 600mm.

Blind flange means that it is a solid disk that is used to block off a pipeline or to create a stoppage at the end of a pipeline.

The flange would be made of a suitable material such as carbon steel or stainless steel, depending on the application and the fluid being transported. It would also have bolt holes around the circumference to allow for easy installation and removal.

Overall, a PN25 DN600 blind flange is a common type of flange used in industrial piping systems for various applications that require a higher pressure rating compared to PN10 flanges.

The advantages of PN25 DN600 Blind Flanges are:

High Pressure Rating: PN25 DN600 Blind Flanges are designed to withstand a working pressure of 25 bar, which makes them ideal for use in piping systems that require a high-pressure rating.

Corrosion and Heat Resistant: These flanges are made from materials that are highly resistant to corrosion, which makes them suitable for use in harsh environments that may be exposed to corrosive substances. They are also designed to withstand high temperatures.

Efficient Blind Flange: Blind flanges are used to seal off an end of a pipeline or to block off a section of the pipeline for maintenance work. The efficiency of PN25 DN600 Blind Flanges ensures the pipeline remains secure when maintenance work is being carried out.

Applications:

Chemical Processing: PN25 DN600 Blind Flanges are commonly used in chemical processing plants due to their ability to withstand corrosion from harsh chemicals.

Power Generation: They are also used in power generation plants, such as nuclear power plants or coal power plants, due to their ability to withstand high temperatures and pressure which is generated.

Water Treatment: PN25 DN600 Blind Flanges are commonly used in water treatment facilities, where they help to secure pipes and pumps from high-pressure water flows.

In summary, PN25 DN600 Blind Flanges are used in various industries that require a high-pressure rating and need to withstand harsh environmental conditions. They are suitable for chemical processing, power generation, and water treatment applications, as well as other heavy-duty industrial applications.

Our Company

Jin Runyuan flange of Shandong Machinery CO., LTD is located in the famous "township of the blacksmith"-Shandong Jinan chapter grave area set street agency headquarters, where convenient transportation beautiful environment. Company was founded in 2001, covers an area of 20000 square meters, is a professional manufacturer of forging flange company, main products: Japanese standard, American standard, German standard, the standard also can according to customers drawings or samples processing. Existing fixed assets of 40 million,the annual output 40 million tons.Products are exported to Japan, the United States, Germany, South Korea, Russia, Brazil, South Africa, more than 20 countries and regions, such as product quality deeply the general customers the high praise and trust.

Company strong technical force, professional experience, equiptment, professional production and technical personnel 10 people, the production of 120 front-line workers, management personnel E people, packing, inspection personnel more than 20 people. High quality international most advanced forging machinery processing, assembly, inspection, packaging production lines, product quality meet the national and international standards, and has obtained ISSO9001-2000 quality management system certification, the French classification society certification, China special equipment manufacturing license, pressure vessel manufacturing license.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor