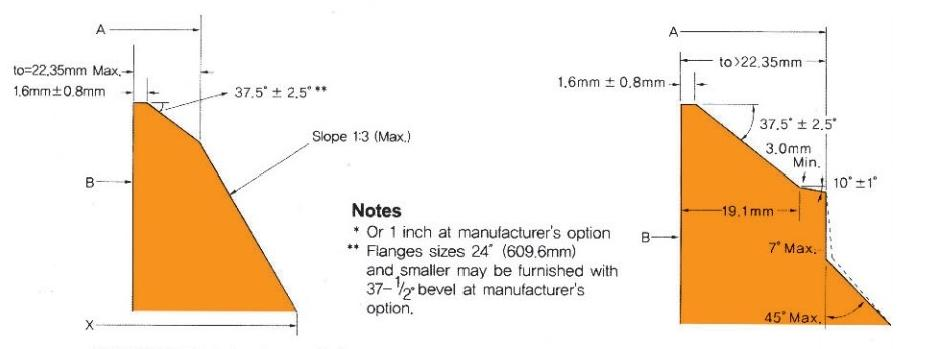

Welding-Ends For Welding Neck Flanges

A welding neck flange (“wn”)capabilities a protracted tapered hub that can be welded with a pipe.

This flange kind is used, commonly, in excessive-pressure and excessive/low temperatures packages that require an unrestricted drift of the fluid conveyed by way of the piping device (the bore of the flange fits with the bore of the pipe).

The absence of strain drops prevents horrible penalties as turbulence and erosion/corrosion of the metals within the proximity of the flanged joints.

The tapered hub allows a clean distribution of the mechanical stress among the pipe and the weld neck flange and enables the execution of radiographic inspections to stumble on possible leakages and welding defects.

The dimension of the flange (nps and the pipe schedule) shall wholesome the dimension of the connecting pipe.

Welding neck flanges mainly have better necks, which improves the pressure and bearing potential of the flanges. the cause is to switch the strain of the pipeline, thereby reducing the harm to the flange, and is appropriate for occasions with high strain and temperature. the primary production strategies are imperative forging, forging and manufacturing, casting, rolling, and so forth. the welding neck flanges produced with the aid of our company are all cast, flange density, the possibility of leakage is small , welding neck flange is more handy for on-website installation, and may leave out the method of welding and scratching.

Nominal Pipe Size | DRILLING |

Pitch Diam | GROOVE DIMENSIONS | Dlam. of Raised Face |

Ring and Groove Number | Approximate Weight(kg) | |||||

Bolt Circle Diam |

Number of Holes |

Diam of Holes |

Width | Depth |

Radius | ||||||

Weld- neck | Blind | ||||||||||

C | P | F | E | R | K | ||||||

12 14 16 | 450.9 514.4 571.5 | 16 20 20 | 31.8 31.8 35.1 | 381.0 419.1 469.9 | 11.9 11.9 11.9 | 7.9 7.9 7.9 | 0.8 0.8 0.8 | 412.8 457.2 508.0 | R57 R61 R65 | 64.41 88.30 112.94 | 78.90 107.05 139.25 |

18 20 22 | 628.7 685.8 743.0 | 24 24 24 | 35.1 35.1 41.1 | 533.4 584.2 635.0 | 11.9 13.5 15.1 | 7.9 9.5 11.1 | 0.8 1.5 1.5 | 574.5 635.0 685.8 | R69 R73 R81 | 138.34 167.37 213.00 | 176.90 223.17 = |

24 | 812.8 | 24 | 41.1 | 692.2 | 16.7 | 11.1 | 1.5 | 749.3 | R77 | 235.41 | 342.00 |

26 28 | 876.3 939.8 | 28 28 | 44.5 44.5 | 749.3 800.1 | 19.8 19.8 | 12.7 12.7 | 1.5 1.5 | 809.8 860.6 | R93 R94 | 274.40 337.90 | 489.00 596.50 |

30 32 34 | 997.0 1054.1 1104.9 | 28 28 28 | 47.8 50.8 50.8 | 857.3 914.4 965.2 | 19.8 23.0 23.0 | 12.7 14.3 14.3 | 1.5 1.5 1.5 | 917,4 984.3 1035.1 | R95 H96 R97 | 394.60 455.90 519.40 | 699.90 814.20 938.00 |

36 38 40 | 1168.4 1092.2 1155.7 | 32 32 32 | 53.8 41.1 44.5 | 1022.4 | 23.0 | 14.3 | 1.5 | 1092.2 | R98 | 578.30 315.30 381.00 | 1105.00 907.70 1079.60 |

42 44 46 | 1206.5 1263.7 1320.8 | 32 32 28 | 44.5 47.8 50.8 | 430.90 478.50 560.20 | 1219.30 1396.60 1587.10 | ||||||

48 50 52 | 1371.6 1428.8 1479.6 | 32 32 32 | 50.8 53.8 53.8 | 626.00 694.00 753.00 | 1767.20 2014.90 2225.40 | ||||||

54 56 58 | 1549.4 1600.2 1651.0 | 28 28 32 | 60.5 60.5 60.5 | 929.90 977.50 1029.70 | 2578.30 2766.10 3025.10 | ||||||

60 | 1701.8 | 32 | 60.5 | 1120.40 | 3299.50 | ||||||

Our Company

Jin Runyuan flange of Shandong Machinery CO., LTD is located in the famous "township of the blacksmith"-Shandong Jinan chapter grave area set street agency headquarters, where convenient transportation beautiful environment. Company was founded in 2001, covers an area of 20000 square meters, is a professional manufacturer of forging flange company, main products: Japanese standard, American standard, German standard, the standard also can according to customers drawings or samples processing. Existing fixed assets of 40 million,the annual output 40 million tons.Products are exported to Japan, the United States, Germany, South Korea, Russia, Brazil, South Africa, more than 20 countries and regions, such as product quality deeply the general customers the high praise and trust.

Company strong technical force, professional experience, equiptment, professional production and technical personnel 10 people, the production of 120 front-line workers, management personnel E people, packing, inspection personnel more than 20 people. High quality international most advanced forging machinery processing, assembly, inspection, packaging production lines, product quality meet the national and international standards, and has obtained ISSO9001-2000 quality management system certification, the French classification society certification, China special equipment manufacturing license, pressure vessel manufacturing license.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor